The rubber industry is on the cusp of a technological revolution, thanks to the latest advancements in peptide-based peptizers. These innovative compounds are set to transform the way rubber products are manufactured, offering new opportunities for enhancing performance, efficiency, and environmental sustainability. This article explores the profound impact of peptide in rubber technology and how peptizer in rubber is shaping the future of this vital industry.

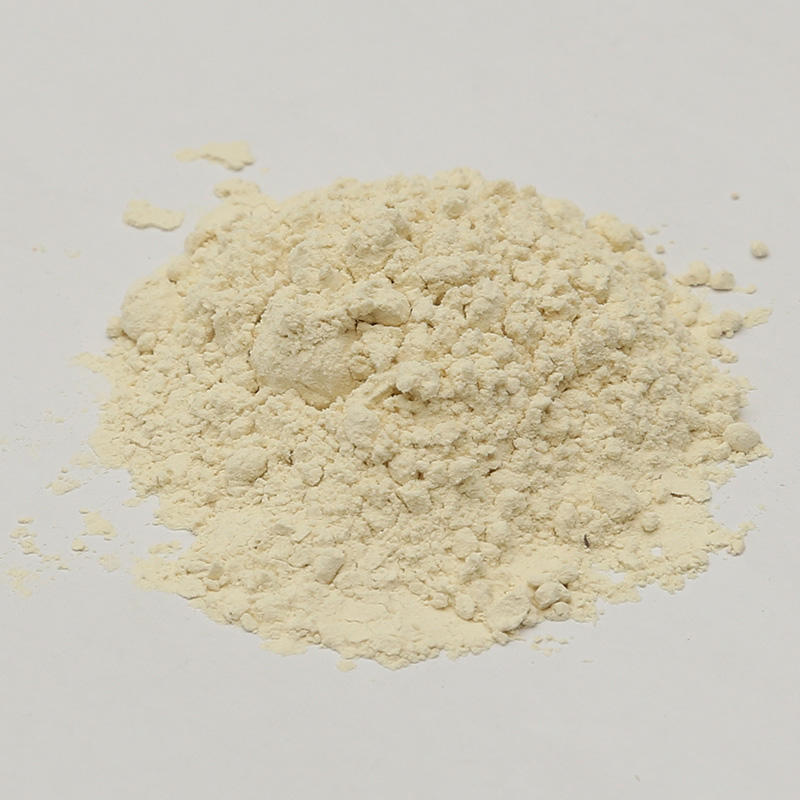

At the heart of this revolution is the concept of peptide-based peptizers—a new class of additives designed to improve the processing and properties of rubber. Peptides, which are short chains of amino acids, have been repurposed from their traditional biological roles to serve as advanced peptizers in rubber formulations. These compounds work by breaking down the polymer chains in rubber, making the material easier to process and enhancing its final properties.

Historically, the rubber industry has relied on conventional peptizers to achieve these effects. However, the introduction of peptide-based peptizers in rubber is bringing a fresh perspective to the field. These advanced peptizers are designed to optimize the rubber’s molecular structure in ways that were previously unattainable with older technologies.

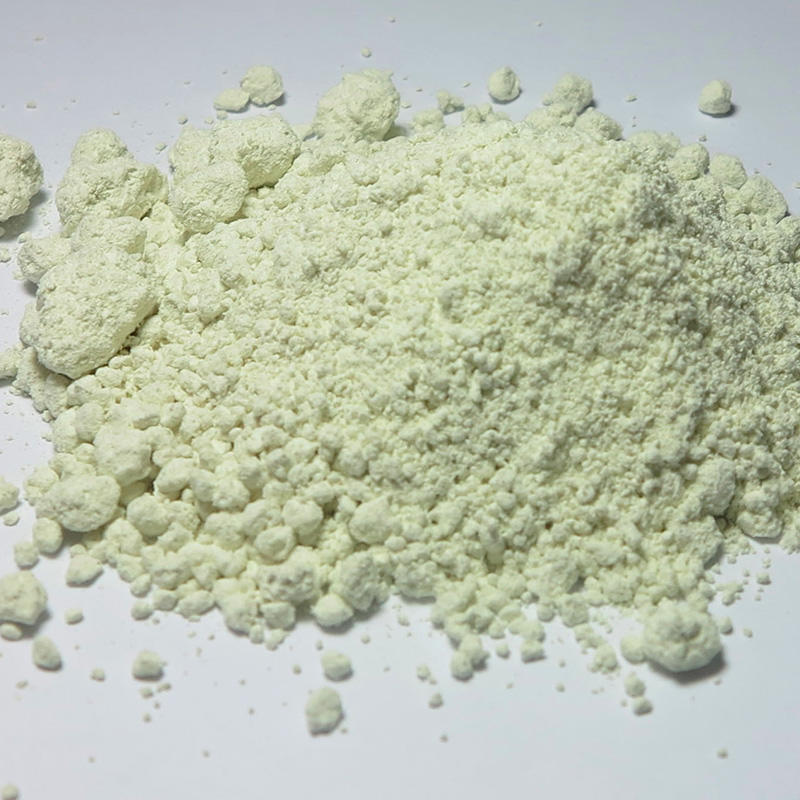

The benefits of incorporating peptide-based peptizers into rubber compounding processes are manifold. One of the significant advantages is the improvement in the mechanical properties of rubber. By using peptide-based peptizers, manufacturers can achieve better elasticity, tensile strength, and wear resistance in their rubber products. These enhancements are crucial for high-performance applications such as automotive tires, industrial belts, and protective coatings.

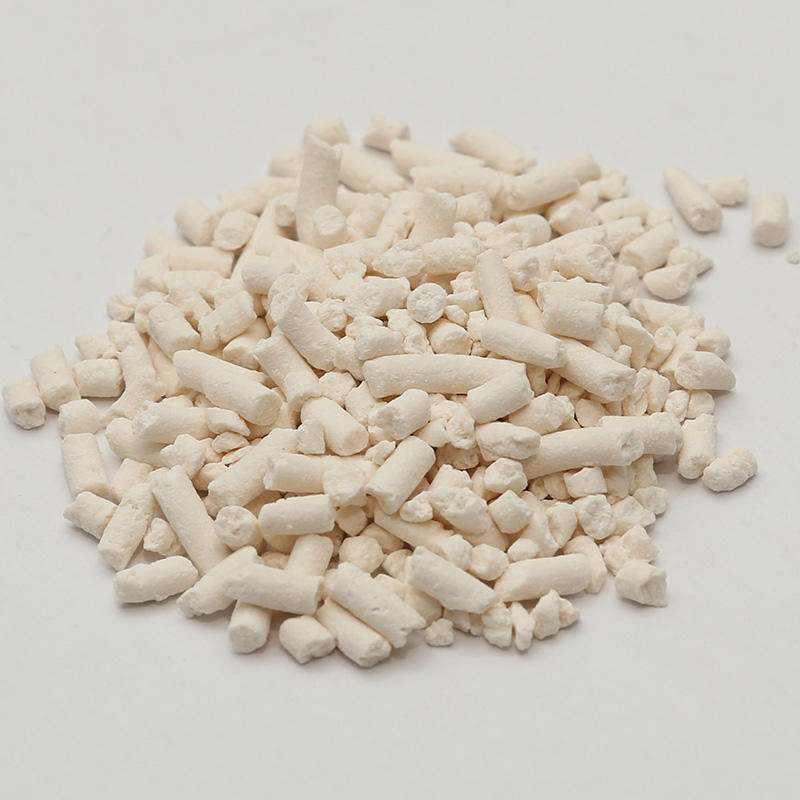

Another key benefit of peptide-based peptizers is the improvement in processability. Traditional rubber compounding methods can be labor-intensive and time-consuming. However, peptide-based peptizers streamline the mixing and processing stages, to increased efficiency and reduced production costs. The use of these advanced peptizers results in a more homogeneous mixture and shorter processing times, which can significantly lower manufacturing expenses.

Moreover, peptide-based peptizers contribute to environmental sustainability. Many modern peptizers are formulated to be eco-friendly, with reduced environmental impacts compared to traditional additives. For example, some peptide-based peptizers are derived from renewable resources and are designed to be biodegradable. This focus on sustainability aligns with the growing industry trend towards greener manufacturing practices.

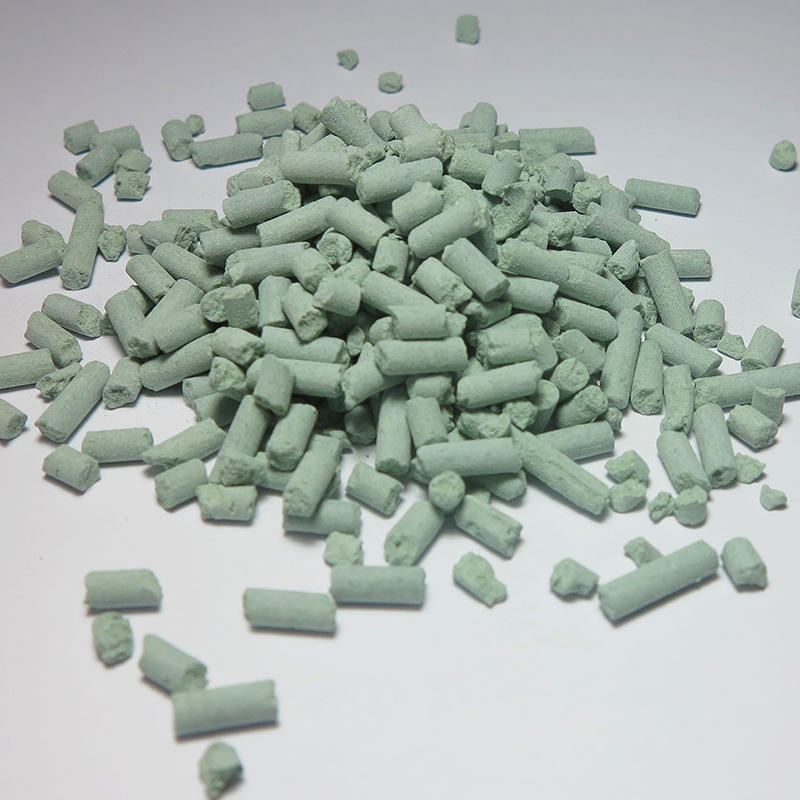

The versatility of peptide-based peptizers makes them suitable for a wide range of applications across different sectors of the rubber industry. In the automotive sector, peptide-based peptizers are used to enhance the performance of tires. The improved mechanical properties provided by these peptizers result in tires with better grip, increased durability, and improved fuel efficiency.

In the industrial sector, peptide-based peptizers are employed to produce high-quality gaskets, seals, and hoses. These components benefit from the enhanced processability and performance characteristics imparted by the peptizers, which ensure reliability and longevity in demanding industrial environments.

The consumer goods sector also reaps the benefits of peptide-based peptizers. Products such as rubber bands, footwear, and playground surfaces all benefit from the improved properties and performance enabled by these advanced additives. By incorporating peptide-based peptizers, manufacturers can produce higher-quality products that meet the evolving demands of consumers.

In the medical field, peptide-based peptizers are used to manufacture critical components for medical devices and pharmaceutical packaging. The high standards for safety and performance in these applications make the advanced properties of peptide-based peptizers especially valuable.

Recent developments in peptide-based peptizers for rubber compounding are pushing the boundaries of what is possible in the rubber industry. One notable innovation is the creation of multifunctional peptizers that offer multiple benefits in a single formulation. These advanced peptizers combine properties such as enhanced performance, improved processability, and environmental friendliness, providing comprehensive solutions for manufacturers.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体