In the ever-evolving field of rubber compounding, the use of peptide technology is creating a transformative shift. The development of advanced peptizer in natural rubber compounding is opening new doors for manufacturers and setting new standards for product performance, efficiency, and sustainability. This article delves into the latest advancements in peptide technology, exploring how peptizer in natural rubber compounding is shaping the future of the rubber industry.

Understanding Peptide Technology in Natural Rubber Compounding

Peptides, short chains of amino acids, have recently found a niche application in the realm of natural rubber compounding. The use of peptizer in natural rubber compounding leverages these peptides to enhance the properties of natural rubber through innovative chemical processes. Essentially, peptizer in natural rubber compounding involves incorporating peptide-based additives into the rubber formulation to modify its polymer chains, improving various aspects of the rubber's performance.

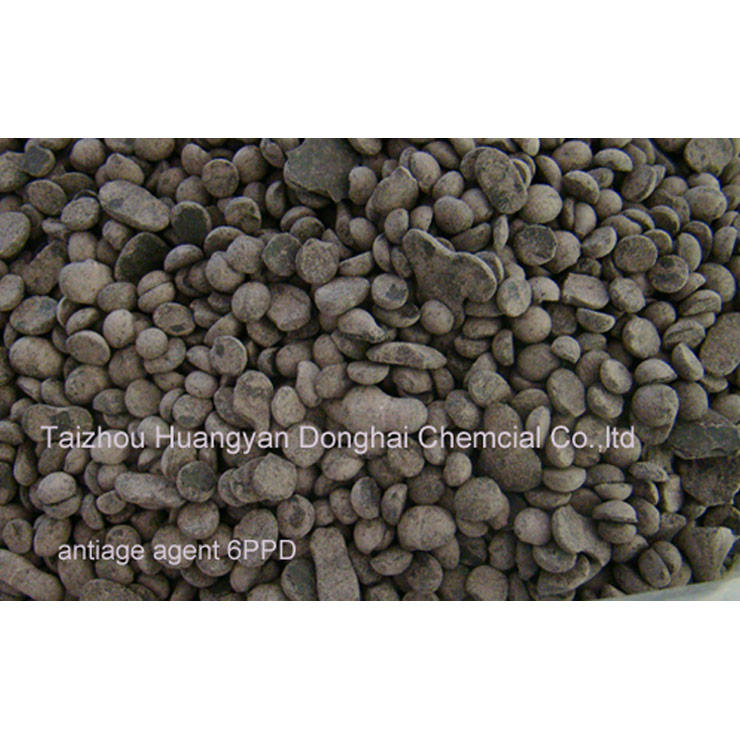

Traditional compounding methods often rely on generic peptizers that may not address specific needs of modern rubber products. However, the introduction of specialized peptizer in natural rubber compounding is driving a new era of tailored solutions that offer improved processability and performance characteristics. This advanced approach is helping manufacturers meet the increasing demands for high-quality and high-performance rubber products.

The introduction of peptizer in natural rubber compounding brings a range of benefits that significantly impact both the production process and the final product. One of the main advantages is the enhancement of the rubber’s physical properties. Peptides used as peptizer in natural rubber compounding help to break down the rubber's polymer chains more effectively, to improved elasticity, strength, and durability.

These benefits translate into better performance for a wide range of applications. For example, in the automotive industry, peptizer in natural rubber compounding is used to develop high-performance tires that offer grip, stability, and longevity. In the industrial sector, peptizer in natural rubber compounding contributes to the creation of robust seals, gaskets, and hoses that perform reliably under demanding conditions.

Another significant advantage of peptizer in natural rubber compounding is the improvement in processing efficiency. Advanced peptide-based peptizers facilitate smoother mixing and better dispersion of additives, reducing production time and costs. By optimizing the compounding process, manufacturers can achieve higher consistency in their products while also minimizing waste.

The applications of peptizer in natural rubber compounding are as diverse as the rubber products themselves. In the automotive sector, peptizer in natural rubber compounding plays a crucial role in the development of high-quality tires. The enhanced properties provided by peptide-based peptizers to tires with improved performance characteristics such as better traction, wear resistance, and overall durability.

In the consumer goods industry, peptizer in natural rubber compounding is used to produce a variety of products, including rubber bands, footwear, and playground surfaces. The flexibility and strength achieved through advanced peptizers result in products that are both functional and aesthetically pleasing.

The medical and pharmaceutical industries also benefit from peptizer in natural rubber compounding. For instance, peptide-based peptizers are used to create high-quality rubber components for medical devices, ensuring that they meet stringent safety and performance standards. Additionally, peptizer in natural rubber compounding contributes to the development of durable and reliable packaging for pharmaceutical products.

The field of peptide-based peptizers for natural rubber compounding is experiencing a surge of innovation. Recent developments include the creation of new peptide formulations that offer enhanced performance and environmental benefits. For example, researchers are developing eco-friendly peptide-based peptizers that reduce the environmental impact of rubber production.

These innovations reflect a broader trend towards sustainability in the rubber industry. The development of bio-based peptides and the use of renewable resources in peptizer in natural rubber compounding are helping manufacturers meet environmental regulations and appeal to eco-conscious consumers.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体