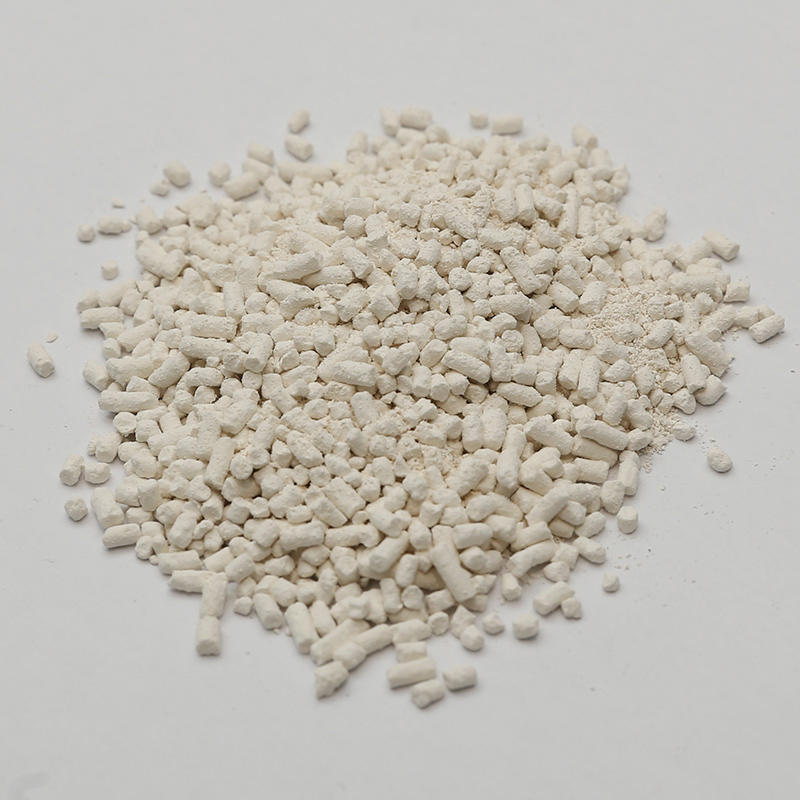

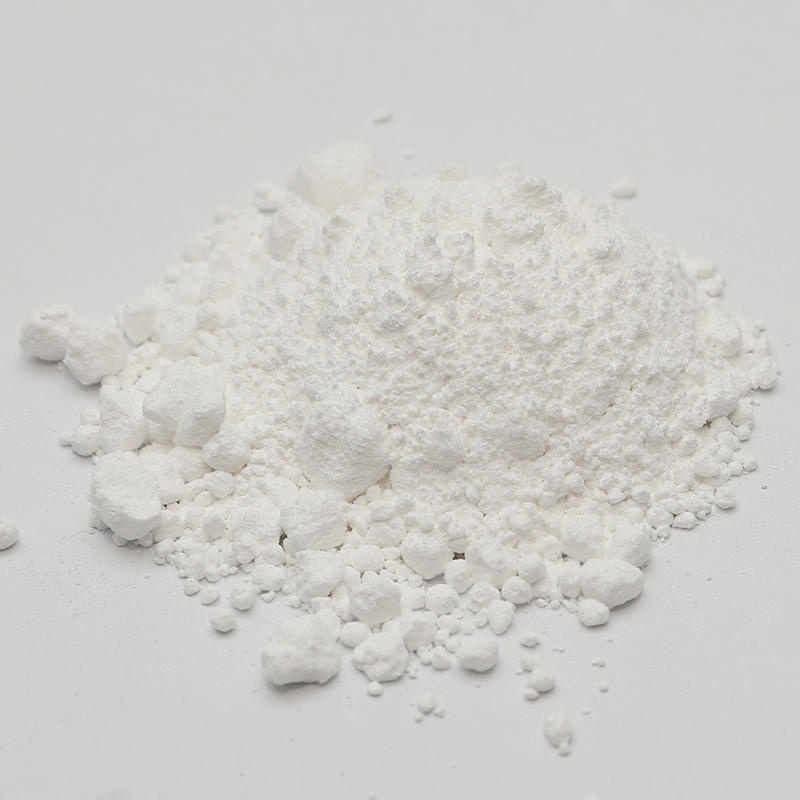

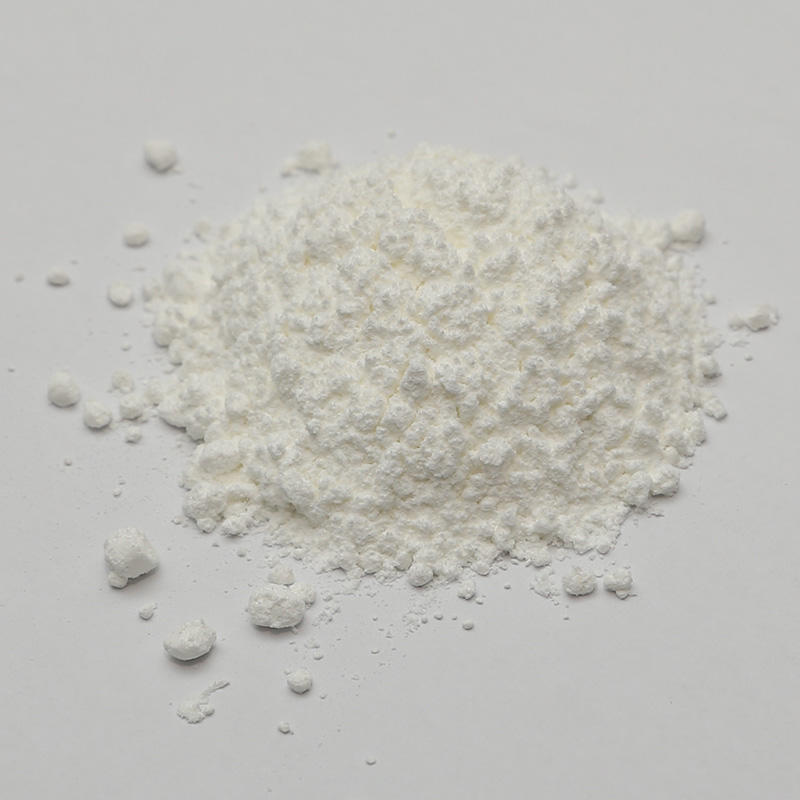

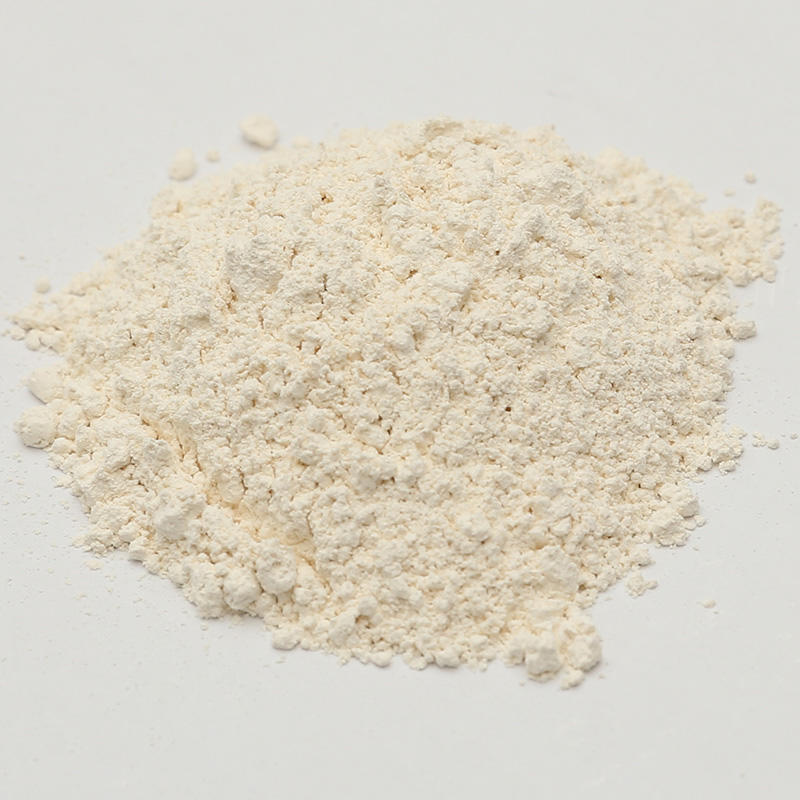

Sale Custom Rubber Tackifying Tackifier Resins Supplier

Rubber Tackifying Resins are a class of polymers that have been instrumental in revolutionizing the quality of rubber goods. These resins are specifically designed to enhance the tackiness, adhesion, and overall performance of rubber compounds. The significance of them in the manufacturing process cannot be overstated, as they directly influence the durability, flexibility, and longevity of rubber products. This article will delve into the profound impact of Rubber Tackifying Resins on the quality of rubber goods and how their use has become a benchmark in the rubber industry.

Sale Rubber Tackifying Resins are a blend of natural and synthetic polymers that, when combined with rubber, create a synergistic effect that improves the material's properties. These resins are carefully formulated to provide the desired level of tackiness without compromising the rubber's other essential characteristics. The addition of it to rubber compounds is a critical step in the manufacturing process, as it ensures that the final product meets higher quality standards.

One of the primary benefits of incorporating Rubber Tackifying Resins into rubber formulations is the enhanced adhesion they provide. This is particularly important in applications where rubber goods need to bond securely with other materials, such as automotive parts, adhesives, and seals. The use of it ensures that these bonds are strong, reliable, and long-lasting, reducing the likelihood of failure and improving the overall performance of the product.

Durability is a key factor in the quality of rubber goods, and Rubber Tackifying Resins play a crucial role in this aspect. By improving the rubber's resistance to wear and tear, these resins extend the life of rubber products, making them more cost-effective and environmentally friendly. The incorporation of Rubber Tackifying Resins into rubber compounds results in a more robust and resilient material that can withstand the rigors of daily use.

Flexibility is another critical property of rubber goods, and Rubber Tackifying Resins contribute significantly to this attribute. By modifying the rubber's molecular structure, these resins allow for greater flexibility without sacrificing strength. This is particularly important in applications where rubber goods are subjected to repeated flexing, such as in hoses, belts, and seals. The use of Custom Rubber Tackifiers ensures that these products maintain their flexibility over time, even under severe conditions.

The environmental impact of Rubber Tackifying Resins is also an important consideration. As the manufacturing industry moves towards more sustainable practices, the use of these resins can help reduce waste and improve the recyclability of rubber products. By enhancing the durability and longevity of rubber goods, Rubber Tackifying Resins contribute to a reduction in the overall environmental footprint of the rubber industry.

Rubber Tackifying Resins are used across a wide range of applications within the manufacturing industry. From automotive components to construction materials, these resins are essential in creating high-quality rubber products. In the tire industry, for example, Rubber Tackifying Resins are used to improve the grip and performance of tires, ensuring safer and more efficient transportation. In the medical sector, these resins are used in the production of rubber gloves and other equipment, where tackiness and adhesion are critical for safety and hygiene.

The impact of Tackifier Resin Suppliers on the quality of rubber goods is undeniable. These resins have become an integral part of the manufacturing process, providing a range of benefits that enhance the performance, durability, and flexibility of rubber products. As the rubber industry continues to evolve, the role of Rubber Tackifying Resins will only grow in importance, driving innovation and setting new standards for quality in rubber goods manufacturing.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体