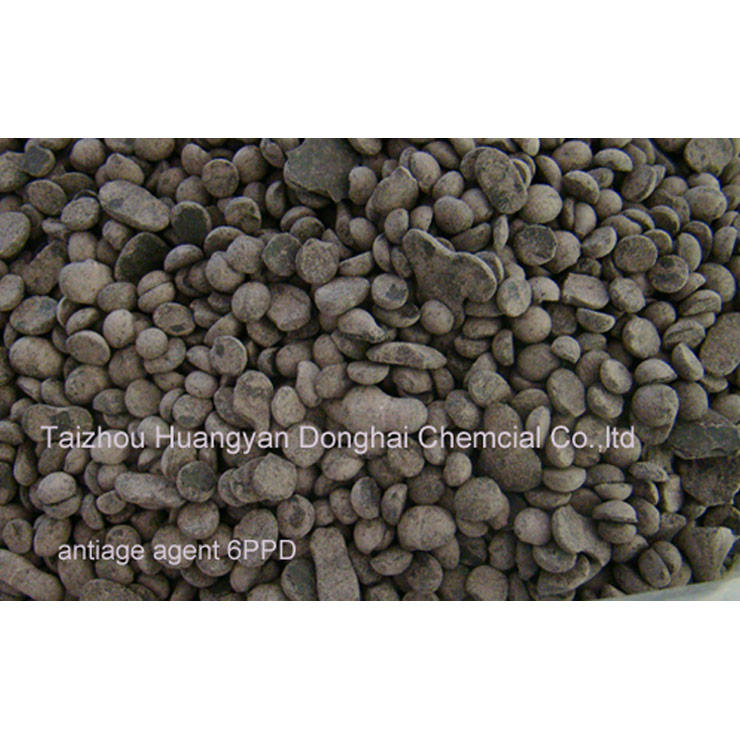

Custom OEM Flexible Rubber Tackifying Resins Manufacturer

Rubber Tackifying Resins play a pivotal role in the manufacturing industry, offering a range of applications that enhance the performance and functionality of various products. These resins are known for their ability to improve the tackiness, adhesion, and elasticity of rubber compounds, making them indispensable in a multitude of industrial processes. This article will explore the versatility of Custom Rubber Tackifying Resins and their significant impact on the manufacturing sector.

Rubber Tackifying Resins are used to modify the properties of rubber, particularly in terms of adhesion. By incorporating these resins into rubber formulations, manufacturers can achieve a higher level of tack, which is crucial for products that require strong bonding capabilities. This is particularly important in the tire and automotive industries, where the adhesion of rubber to metal components is essential for safety and performance.

Elasticity is a key characteristic of rubber, and Rubber Tackifying Resins can significantly enhance this property. By improving the elasticity of rubber compounds, these resins contribute to the production of more durable and flexible products. This is especially relevant in the manufacturing of hoses, seals, and gaskets, where flexibility and resilience are paramount.

The processability of rubber is another area where Rubber Tackifying Resins excel. They can facilitate easier processing by reducing the viscosity of rubber compounds, which in turn can result in more efficient manufacturing processes. This is particularly beneficial in industries where large volumes of rubber products are produced, as it can help to reduce production times and costs.

Applications of Rubber Tackifying Resins in the Manufacturing Industry. In the tire manufacturing industry, they are used to improve the adhesion between the rubber and the steel belts within the tire. This ensures that the tire maintains its structural integrity and provides a safe and stable ride for the user.

They are integral in the production of automotive seals and gaskets. They enhance the sealing properties of these components, ensuring that they can withstand high temperatures and pressures while maintaining a tight seal.

The adhesive and sealant industry relies heavily on OEM Flexible Rubber Resin to create products with strong bonding capabilities. These resins are used in the formulation of construction adhesives, which are critical for bonding various materials together in building and construction projects.

In the footwear industry, Rubber Tackifying Resins are used to improve the durability and flexibility of shoe soles. They contribute to the production of soles that are comfortable to walk on and can withstand the wear and tear of daily use.

Rubber Tackifying Resins also find application in the manufacturing of medical devices, particularly in the production of rubber components that require a high level of adhesion and elasticity. This is crucial for devices that come into contact with the human body, where comfort and safety are of paramount importance.

Challenges and Solutions in Using Rubber Tackifying Resins. One of the challenges faced when using it is ensuring compatibility with the base rubber compound. Incompatibilities can result in poor performance and reduced product quality. To address this, manufacturers must carefully select resins that are compatible with their specific rubber formulations.

Rubber Tackifying Resins can be sensitive to processing temperatures. High temperatures can cause the resins to degrade, while low temperatures can make them difficult to incorporate into the rubber. Manufacturers must optimize their processing conditions to ensure that the resins are effectively incorporated without degradation.

Rubber Tackifying Resins are a versatile component in the manufacturing industry, offering a range of benefits from improved adhesion to enhanced elasticity. As the industry continues to evolve, the development of new and improved resins will be crucial to meet the demands of a diverse range of applications. By understanding the properties and challenges associated with Rubber Resins Manufacturers, manufacturers can optimize their use and create high-quality products that meet the needs of consumers and industries alike.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体