In the ever-evolving field of rubber technology, the latest advancements in peptizer for natural rubber are setting new benchmarks for performance and environmental sustainability. These innovative compounds, which harness the power of peptides, are revolutionizing the way natural rubber is processed and used across various industries. This article explores the transformative impact of peptizer for natural rubber, detailing its benefits, applications, and future prospects.

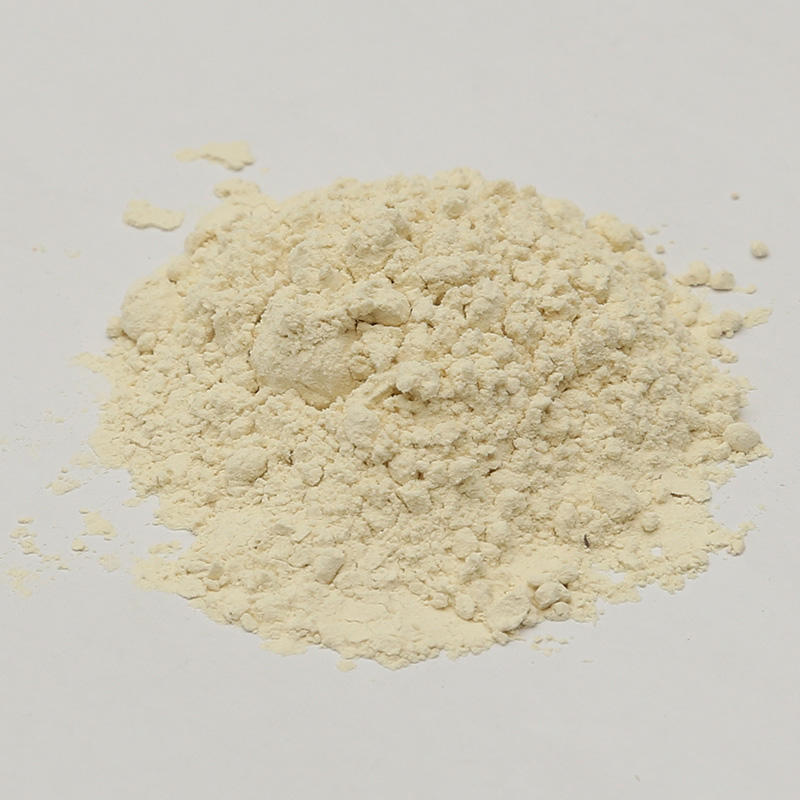

Peptizer for natural rubber refers to the use of peptide-based additives to improve the processing and properties of natural rubber. Peptides, which are short chains of amino acids, have been employed in this innovative approach to modify the polymer chains in natural rubber, thereby enhancing its characteristics. Traditional peptizers are often based on more generic chemical compounds, but the introduction of peptide-based alternatives offers new possibilities for optimizing rubber performance.

By using peptizer for natural rubber, manufacturers can break down the rubber’s polymer chains in a controlled manner. This process, known as peptization, helps achieve a more consistent rubber mixture, improves mechanical properties, and enhances overall product quality.

The advantages of integrating peptizer for natural rubber into compounding processes are profound. One of the significant benefits is the enhancement of the rubber's mechanical properties. Peptizer for natural rubber can increase elasticity, tensile strength, and durability, making it ideal for high-performance applications such as automotive tires, industrial components, and consumer products.

The improved processability offered by peptizer for natural rubber is another notable advantage. These advanced peptizers streamline the mixing and processing stages, reducing the time and energy required to achieve a homogeneous rubber mixture. This efficiency translates into cost savings for manufacturers and supports the development of more complex and high-quality rubber products.

Environmental sustainability is also a key benefit of using peptizer for natural rubber. Many of the latest peptide-based peptizers are designed to be eco-friendly, with formulations that are biodegradable and derived from renewable resources. This aligns with the broader industry trend towards greener manufacturing practices and helps manufacturers meet stringent environmental regulations.

The versatility of peptizer for natural rubber extends across a range of applications, demonstrating its broad impact on the rubber industry. In the automotive sector, peptizer for natural rubber is used to enhance the performance of tires. The improved mechanical properties and processability offered by these advanced peptizers to the production of tires with grip, durability, and fuel efficiency.

In the industrial sector, peptizer for natural rubber is employed to create high-quality seals, gaskets, and hoses. These components benefit from the enhanced strength and flexibility provided by peptide-based peptizers, ensuring they can withstand demanding operational conditions.

The consumer goods industry also leverages peptizer for natural rubber to produce a variety of products, including rubber bands, footwear, and playground surfaces. The advanced properties of these peptizers enable the creation of high-performance, durable products that meet the expectations of modern consumers.

In the medical and pharmaceutical fields, peptizer for natural rubber is used to manufacture essential components for medical devices and packaging. The ability to produce safe, reliable, and high-quality rubber components is crucial in these applications, making peptide-based peptizers a valuable tool for achieving these goals.

The field of peptizer for natural rubber is marked by a series of exciting innovations. Researchers are continually developing new peptide formulations that offer enhanced performance and environmental benefits. For example, recent advancements include the creation of multifunctional peptizers that provide multiple advantages in a single product, such as improved mechanical properties, better processability, and reduced environmental impact.

Another significant innovation is the development of bio-based peptizer for natural rubber products. These eco-friendly formulations are derived from renewable resources and are designed to be biodegradable. This shift towards bio-based peptizers reflects a growing emphasis on sustainability within the rubber industry.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体