Sale Cheap Rubber Bonding Additives Agent Composite Resin Price

The rubber industry is a cornerstone of modern manufacturing, with rubber products being integral to a wide range of applications, from automotive tires to industrial hoses and seals. The versatility and durability of rubber are not inherent but are significantly enhanced by the inclusion of rubber additives. These substances are critical in determining the performance, longevity, and safety of rubber products. In this article, we will discuss the role of rubber additives in the production of industrial rubber products and how they contribute to the industry's success.

Rubber additives are compounds or materials that are added to rubber before or during the vulcanization process to improve its properties or to facilitate the manufacturing process. They play a crucial role in enhancing the performance characteristics of rubber, such as its resistance to heat, ozone, and abrasion, as well as its flexibility, strength, and durability. The use of it is a delicate balance of chemistry and engineering, as they must be carefully selected and combined to achieve the desired outcome without compromising the product's integrity.

One of the primary categories of Bonding Agent Composite Resin Prices is vulcanization agents. These are essential for the process of vulcanization, which involves the cross-linking of rubber molecules to give the material its strength and elasticity. Sulfur is a traditional vulcanization agent, but there are also various accelerators and activators that can be used to control the rate and conditions of the vulcanization process. The right combination of these additives can significantly impact the properties of the rubber product.

Another critical group of rubber additives is plasticizers. These additives are used to increase the flexibility and workability of rubber compounds. Phthalate esters and adipate esters are common plasticizers that are used in a variety of rubber products, from hoses to seals. The selection of the appropriate plasticizer is crucial, as it can affect the product's flexibility, durability, and resistance to environmental factors such as temperature and UV radiation.

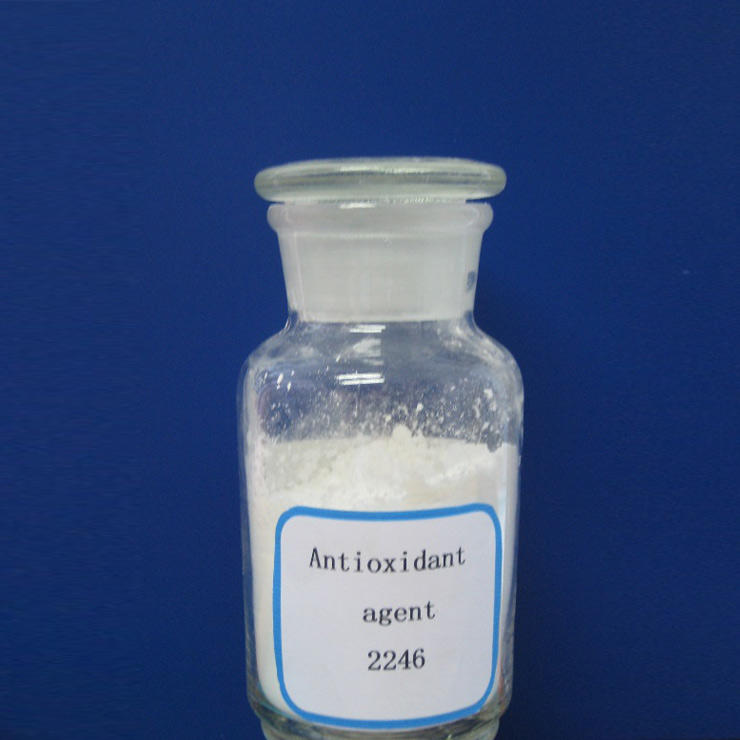

Antidegradants are another class of rubber additives that are vital for the longevity of rubber products. These additives protect rubber from the damaging effects of heat, oxygen, and ozone, which can cause the material to crack and deteriorate over time. Antidegradants work by forming a protective barrier on the surface of the rubber or by reacting with the damaging agents to neutralize their effects. This extends the service life of rubber products and ensures their reliability in critical applications.

The role of rubber additives extends beyond just enhancing the physical properties of rubber. They also play a significant role in the processing of rubber compounds. Processing aids, for example, are rubber additives that improve the flow and mixing characteristics of rubber during manufacturing. This can result in more uniform and consistent products, reducing waste and improving efficiency in the production process.

The sale Rubber additives also contributes to the safety and environmental performance of rubber products. Flame retardants are a type of additive that can be incorporated into rubber to reduce its flammability, making it suitable for use in applications where fire safety is a concern. Similarly, there are rubber additives that can help reduce the emission of harmful substances from rubber during its production and use, contributing to the development of more sustainable and eco-friendly products.

The development and application of Cheap Bonding Additives are a testament to the innovation and adaptability of the rubber industry. As new challenges and requirements emerge, the industry continues to research and develop new additives to meet these needs. For instance, the growing demand for more sustainable products has led to the development of bio-based ones, which are derived from renewable resources and are more environmentally friendly.

In conclusion, rubber additives are the unsung heroes of the rubber industry. They are the key components that enable the production of a wide range of industrial rubber products with the desired properties and performance characteristics. From enhancing the strength and durability of rubber to improving its processing and environmental performance, they play a crucial role in the success of the rubber industry. As the industry continues to evolve, the development and application of rubber additives will remain a critical area of focus, ensuring that rubber products can meet the diverse and demanding needs of modern society.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体