Custom OEM Rubber Additives Chemical Curing Bonding Agent in China

In the realm of polymer science, rubber additives play a pivotal role in enhancing the stability and performance of rubber products. These chemical compounds are the unsung heroes that ensure the resilience, durability, and reliability of rubber in various applications. From tires to seals, hoses to gaskets, the presence of Custom rubber additives is indispensable for maintaining the integrity and functionality of rubber goods. This article delves into the significance of rubber additives and their impact on the stability of rubber.

Rubber, in its natural state, is a versatile material with unique properties such as elasticity and flexibility. However, it is the incorporation of rubber additives that truly unlocks the full potential of this material. These additives are carefully selected and blended to improve specific characteristics of rubber, such as its resistance to heat, ozone, and abrasion. They also play a crucial role in the processing of rubber, facilitating easier manufacturing and molding.

One of the primary functions of rubber additives is to provide thermal stability. Rubber products are often subjected to high temperatures during their service life, and without the right additives, they can degrade and lose their structural integrity. Antioxidants, for instance, are rubber additives that prevent the oxidation of rubber, which can result in chain scission and a loss of strength. By slowing down the rate of thermal degradation, these additives extend the lifespan of rubber products and ensure their reliability in high-temperature environments.

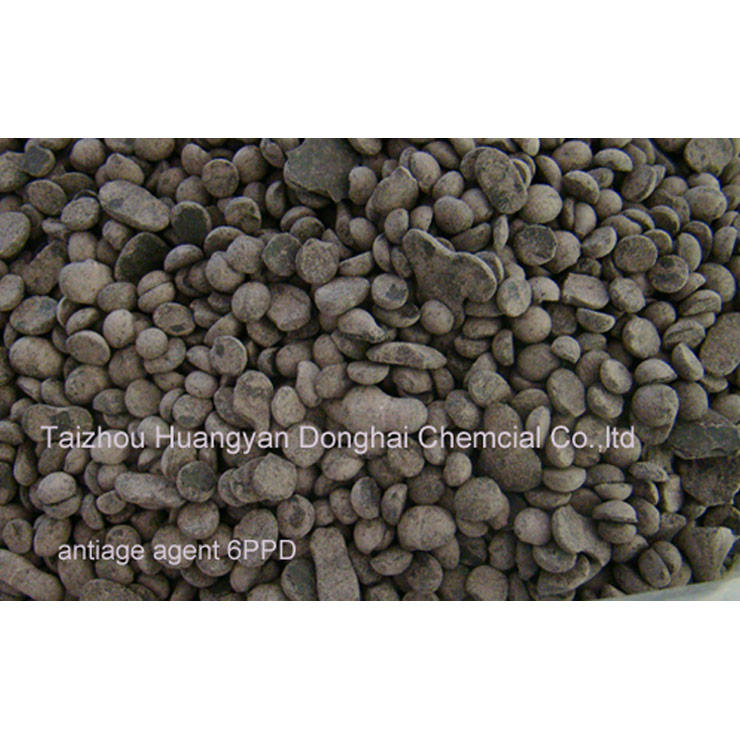

Another critical aspect of rubber stability is its resistance to ozone. Ozone is a highly reactive molecule that can cause cracks in the rubber, resulting in its premature failure. Antidegradants, a type of rubber additive, are specifically designed to protect rubber from ozone attack. They form a protective barrier on the surface of rubber, preventing ozone from penetrating and causing damage. This is particularly important for rubber products that are exposed to outdoor conditions, such as tires and seals.

Rubber additives also play a vital role in enhancing the mechanical properties of rubber. Reinforcing agents, such as carbon black and silica, are added to rubber to improve its tensile strength and tear resistance. These additives help to distribute stress evenly throughout the rubber matrix, making it more resistant to wear and tear. The result is a rubber product that is more durable and less prone to failure under stress.

Processing aids are another category of OEM Curing Bonding Agent that facilitates the manufacturing process. These additives improve the flow and mixing of rubber compounds, making it easier to mold and shape the rubber into various forms. They also help to reduce the energy required for processing, resulting in more efficient production and lower manufacturing costs.

The stability of rubber in various environmental conditions is also significantly influenced by rubber additives. For example, plasticizers are used to increase the flexibility and elasticity of rubber, making it more resistant to cracking in cold temperatures. On the other hand, flame retardants are added to rubber to prevent it from catching fire or to slow down the spread of flames, ensuring the safety of rubber products in high-risk environments.

Rubber additives are also essential in providing color and aesthetic appeal to rubber products. Pigments and dyes are used to give rubber its desired color, while UV stabilizers protect the rubber from the degrading effects of ultraviolet radiation. This not only enhances the visual appeal of rubber products but also helps to maintain their physical properties over time.

In conclusion, rubber additives are the driving force behind the stability and performance of rubber products. They are the key components that enable rubber to meet the diverse demands of various industries. From enhancing the mechanical properties to providing resistance to environmental factors, rubber additives play a multifaceted role in ensuring the reliability and longevity of rubber goods. As the rubber industry continues to evolve, the development and application of Chemical Bonding Agent in China will remain a critical area of focus, driving innovation and improving the performance of rubber products worldwide.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体