The rubber industry is witnessing a groundbreaking shift with the advent of peptide-based technologies. At the forefront of this revolution is the use of peptizer in rubber compounding, a technique that is redefining the way natural rubber is processed and utilized across various sectors. This article explores how the latest advancements in peptizer in rubber compounding are transforming the industry, offering new opportunities for improved performance, efficiency, and sustainability.

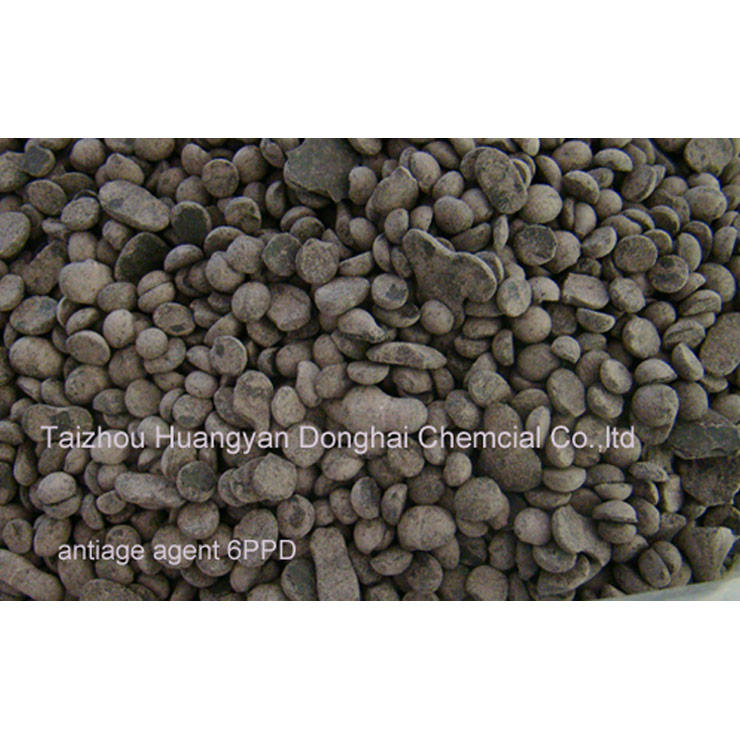

In the context of rubber compounding, a peptizer refers to a specific type of additive used to modify the properties of natural rubber. Peptide-based peptizer in rubber compounding leverages short chains of amino acids—peptides—that have been engineered to enhance the rubber’s physical and chemical properties. By incorporating these advanced peptizers into the rubber formulation, manufacturers can achieve better processability and improved performance characteristics for their products.

Traditional rubber compounding methods often rely on conventional peptizers that offer limited benefits. In contrast, peptizer in rubber compounding utilizes the unique properties of peptides to achieve a more effective breakdown of polymer chains, to rubber properties and more efficient manufacturing processes.

The introduction of peptizer in rubber compounding has brought several notable benefits to the rubber industry. One of the primary advantages is the enhancement of the rubber’s mechanical properties. Peptide-based peptizers facilitate the controlled breakdown of polymer chains, resulting in natural rubber with improved elasticity, tensile strength, and durability. These improvements are crucial for applications that demand high performance and reliability, such as in automotive tires, industrial machinery, and high-quality consumer products.

Another significant benefit of peptizer in rubber compounding is the increased efficiency of the compounding process. Advanced peptide-based peptizers enable smoother mixing and better dispersion of additives, which reduces production time and costs. This enhanced efficiency allows manufacturers to produce rubber products more quickly and with greater consistency, to cost savings and higher quality outcomes.

Environmental sustainability is also a key advantage of peptide-based peptizers. Many of these new peptizers are designed to be eco-friendly, with formulations that are biodegradable and derived from renewable resources. The use of such sustainable additives aligns with the growing trend towards environmentally responsible manufacturing practices in the rubber industry.

The versatility of peptizer in rubber compounding extends across various applications, demonstrating its broad impact on the rubber industry. In the automotive sector, peptizer in rubber compounding is used to enhance the performance of tires. The improved mechanical properties and processing efficiency provided by peptide-based peptizers result in tires with better grip, longer wear life, and increased fuel efficiency.

In the industrial sector, peptizer in rubber compounding is employed to create high-quality components such as seals, gaskets, and hoses. The advanced properties of these peptizers ensure that these components perform reliably under demanding conditions, making them essential for a wide range of industrial applications.

The consumer goods sector also benefits from peptizer in rubber compounding. Products such as rubber bands, footwear, and playground surfaces are all improved by the use of peptide-based peptizers. The enhanced performance and durability of these products meet the high standards expected by consumers.

In the medical and pharmaceutical fields, peptizer in rubber compounding plays a crucial role in the production of medical devices and packaging. The ability to produce high-quality, reliable rubber components is essential in these applications, and peptide-based peptizers provide the necessary improvements to meet strict regulatory standards.

Recent developments in peptizer in rubber compounding are pushing the boundaries of what is possible in the rubber industry. One of the exciting innovations is the creation of multifunctional peptide-based peptizers. These advanced compounds offer a combination of benefits, including enhanced mechanical properties, improved processability, and environmental sustainability, all in a single formulation.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体