China Sale Adhesive Acrylic Sheet Bonding Agent Maker

In the realm of manufacturing, the role of adhesive agents is paramount. These substances, known for their ability to bind materials together, have revolutionized the way products are created and assembled. The versatility of adhesive agents is a testament to their importance in various industries, from automotive to aerospace, and from construction to consumer electronics.

Adhesive agents have been a cornerstone of human innovation for centuries. From the ancient use of natural adhesives like tree resin to modern synthetic varieties, the evolution of adhesives has been closely tied to the development of manufacturing processes. Today, China Adhesive Agents are engineered to meet specific needs, offering a range of properties such as temperature resistance, chemical resistance, and flexibility.

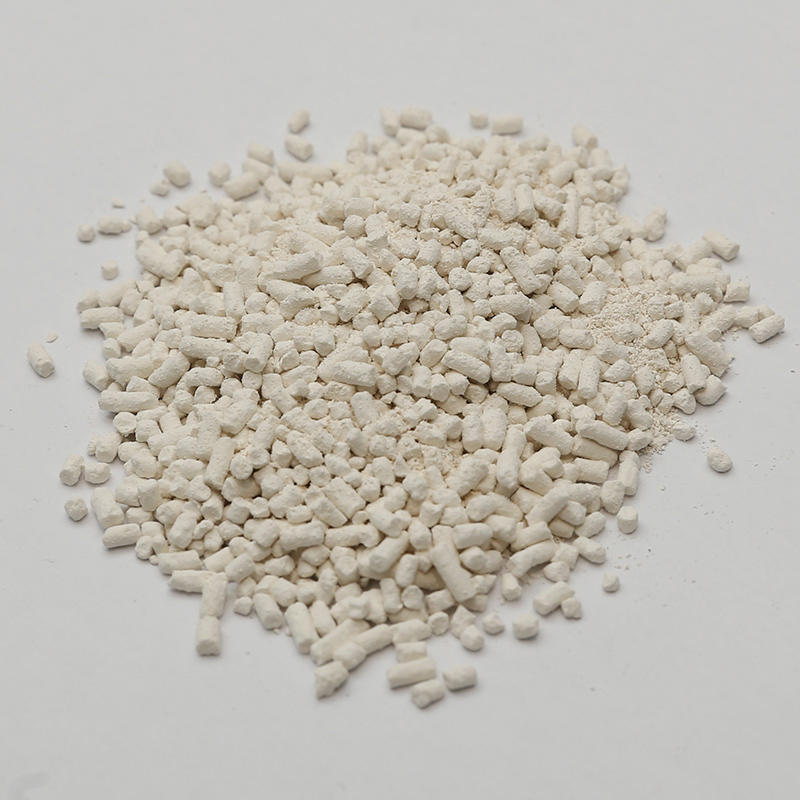

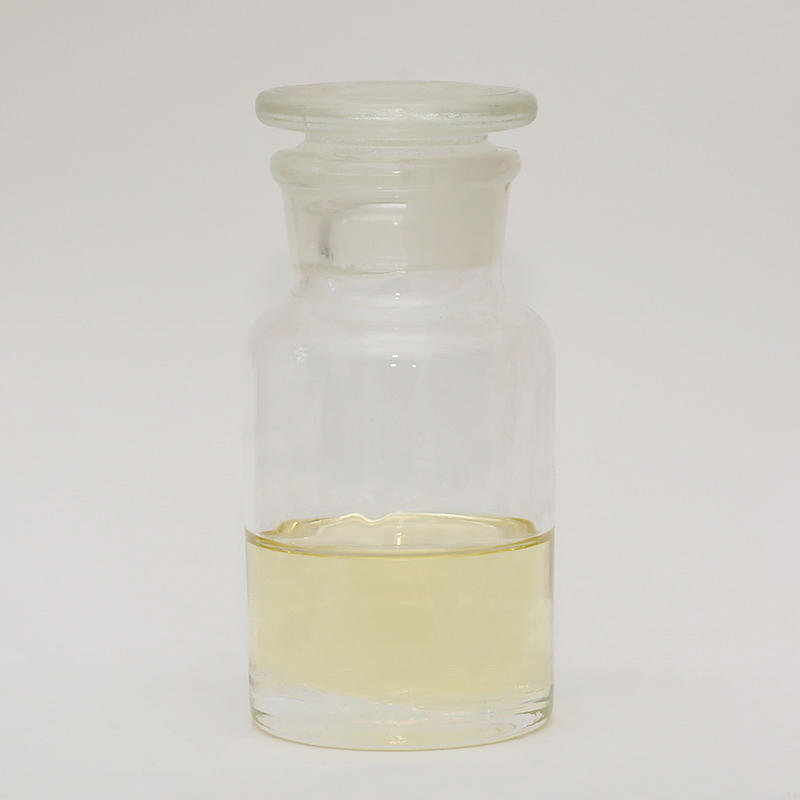

The chemistry behind adhesive agents is complex and diverse. They can be classified into several categories based on their composition and curing mechanism. These are environmentally friendly and easy to clean up, making them popular in woodworking and paper products. Known for their strong bonding capabilities, they are used in applications requiring high durability. These adhesives are applied in a molten state and cool to form a bond, ideal for packaging and assembly lines. They require light pressure to create a bond and are found in tapes, labels, and medical applications. Designed for high-strength bonding, these are used in critical load-bearing applications.

The versatility of adhesive agents is evident in their widespread applications across manufacturing sectors. They are used for bonding car body parts, sealing, and noise reduction. In this industry, adhesives are crucial for joining composite materials in aircraft structures, ensuring lightweight and strong bonds.

Adhesives are used for bonding various materials in building construction, including wood, concrete, and metal. Sale Additive Bonding Agents play a critical role in the assembly of electronic devices, providing both mechanical support and electrical insulation. They are essential for sealing and securing packages and ensuring product integrity during transport.

As manufacturing processes become more sophisticated, so too does the technology behind adhesive agents. These are designed to withstand severe heat, crucial for applications in engines or other high-temperature environments. They cure rapidly upon exposure to ultraviolet light, speeding up production processes. These cutting-edge adhesives can repair themselves after being damaged, extending the lifespan of the bonded materials. They allow for the creation of electrical pathways within a bond, useful in electronic device manufacturing.

The push for sustainable manufacturing practices has led to the development of eco-friendly adhesive agents. Derived from renewable resources, these adhesives reduce the industry's carbon footprint. They emit fewer harmful chemicals into the atmosphere, improving worker safety and environmental health.

Despite their many benefits, adhesive agents also present challenges, such as: Ensuring a strong bond between dissimilar materials can be difficult. Some adhesives require extended periods to cure fully, which can slow down production lines. Adhesive performance can be affected by environmental conditions.

To address these challenges, manufacturers are investing in research and development to create adhesive agents that are more adaptable and reliable.

The role of Acrylic Sheet Bonding Agent Makers in manufacturing is multifaceted and indispensable. As technology advances, the development of new them continues to push the boundaries of what is possible in the world of manufacturing. From improving production efficiency to enhancing product quality, the versatility of is a driving force behind innovation in the industry.

In conclusion, adhesive agents are not just substances that bind; they are the very fabric that holds together the complex and intricate processes of modern manufacturing. As we continue to explore and innovate, the future of adhesive agents looks as strong and durable as the bonds they create.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体