Wholesale Cheap Adhesive Masonry Bonding Agent Composite Factory

The quest for sustainable development has led to a surge in eco-friendly innovations across industries. Adhesive agents, integral to manufacturing processes, are no exception. This article delves into the evolution, benefits, and future of sustainable Wholesale Adhesive Agents, emphasizing their role in creating a greener manufacturing landscape.

In the face of environmental challenges, the manufacturing sector is increasingly adopting sustainable practices. Adhesive agents, traditionally derived from petroleum-based products, are now being reimagined to align with eco-friendly principles. The shift towards sustainable adhesive agents is not just a response to regulatory pressures but also a commitment to preserving the planet for future generations.

Traditional adhesive agents have been the backbone of various manufacturing processes due to their ability to bond different materials effectively. However, the environmental impact of these agents, from production to disposal, has prompted a search for alternatives. The evolution of them has seen a transition from synthetic to bio-based materials, offering a more sustainable option.

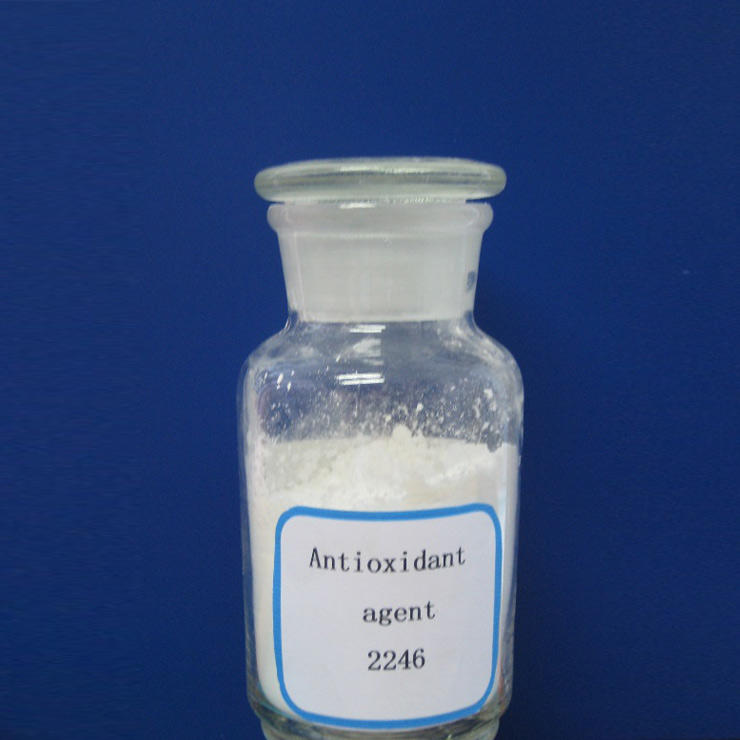

Types of Sustainable Adhesive Agents. Derived from renewable resources such as starch, cellulose, and lignin, these adhesives are biodegradable and have a lower carbon footprint. Replacing solvent-based adhesives, water-based options reduce volatile organic compound (VOC) emissions and are easier to clean up. These agents cure through chemical reactions, often resulting in stronger bonds and less waste. While not always sustainable, some hot-melt formulations use bio-based materials, reducing their environmental impact.

Sustainable Cheap Masonry Bonding Agents are gaining prominence as a key component in the manufacturing sector's drive toward environmental responsibility. These eco-friendly alternatives not only contribute to a lower carbon footprint by reducing the emission of volatile organic compounds (VOCs) but also minimize pollution through biodegradable and non-toxic formulations. Compliance with stringent environmental regulations is a significant advantage, as it allows manufacturers to operate within legal boundaries while also promoting a positive public image.

The burgeoning market for green products has created a demand for companies to showcase their commitment to sustainability. By incorporating sustainable adhesive agents into their production processes, companies can bolster their environmental credentials, appealing to consumers who prioritize eco-conscious purchasing decisions. Although the upfront investment in sustainable adhesive agents might be more substantial, the long-term economic benefits are compelling. These include savings on waste management through reduced disposal costs, potential eligibility for government tax incentives that support green initiatives, and the enhancement of a brand's reputation in the eyes of environmentally aware consumers. This strategic shift towards sustainability can result in increased market share and customer loyalty, ultimately contributing to a company's long-term profitability and success.

Challenges in Implementing Sustainable Adhesive Agents. The production of sustainable can be more expensive due to the use of novel materials and processes. Ensuring that meet the performance standards of their traditional counterparts is a significant challenge. The availability and scalability of raw materials for sustainable adhesive agents can be a limiting factor.

The future of Bonding Agent Composite Factory is promising, with ongoing research and development focusing on enhancing performance and reducing the cost of sustainable options. Innovations in nanotechnology and bioengineering are expected to yield adhesive agents with bonding capabilities and environmental benefits.

Sustainable adhesive agents are a critical component of the manufacturing industry's transition towards eco-friendly practices. As the demand for green products grows and regulatory frameworks tighten, the adoption of sustainable adhesive agents will become increasingly important. By embracing these innovations, manufacturers can contribute to a more sustainable future while maintaining product quality and performance.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体