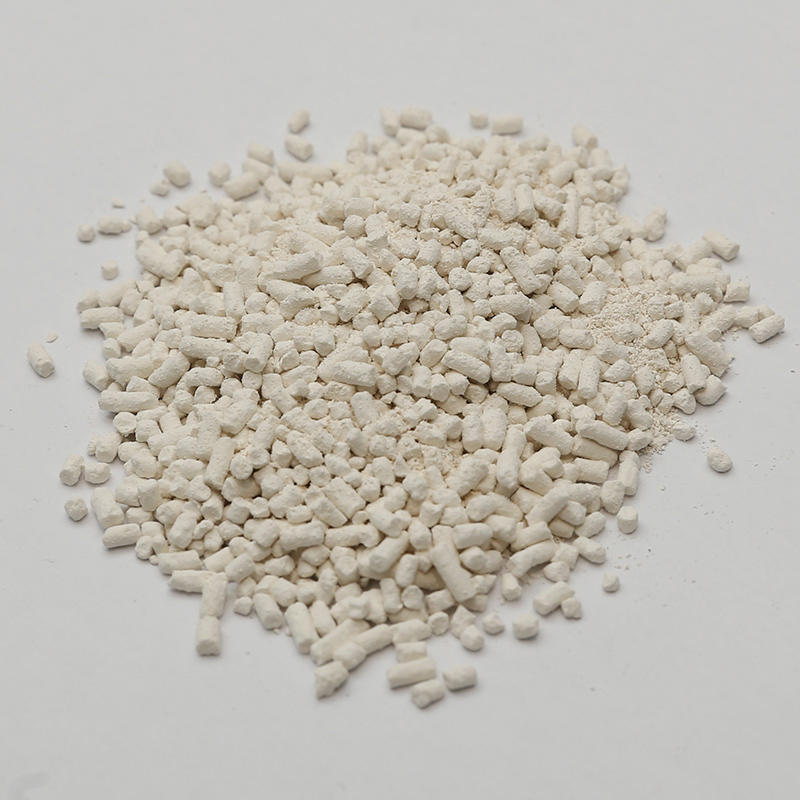

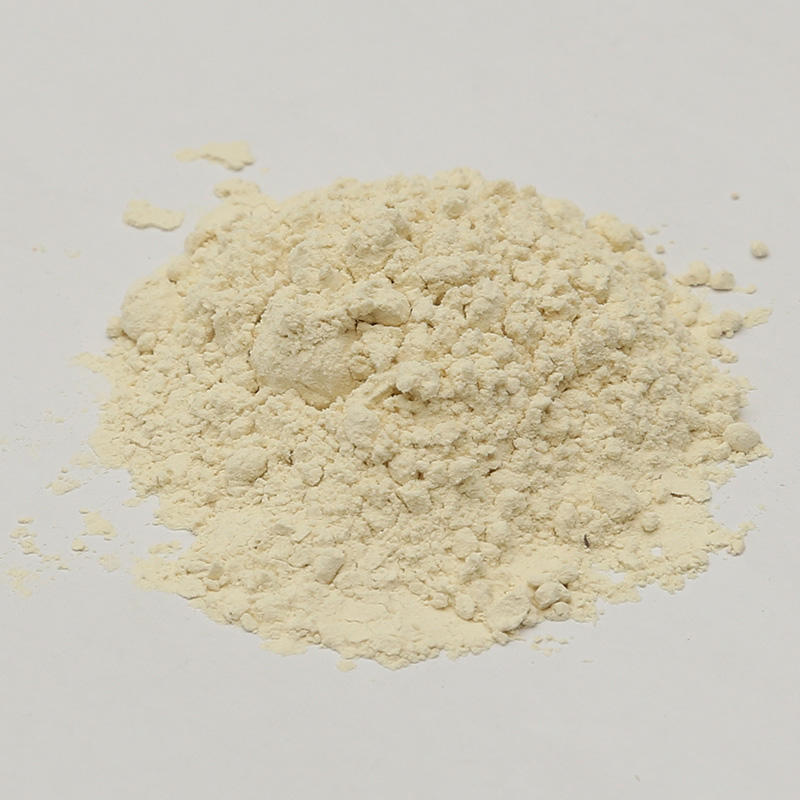

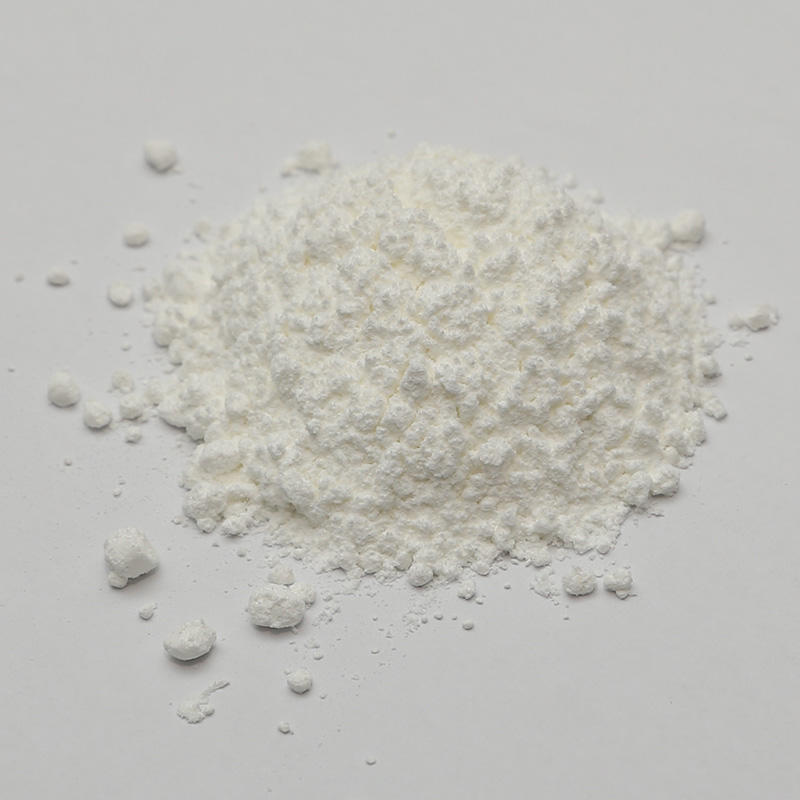

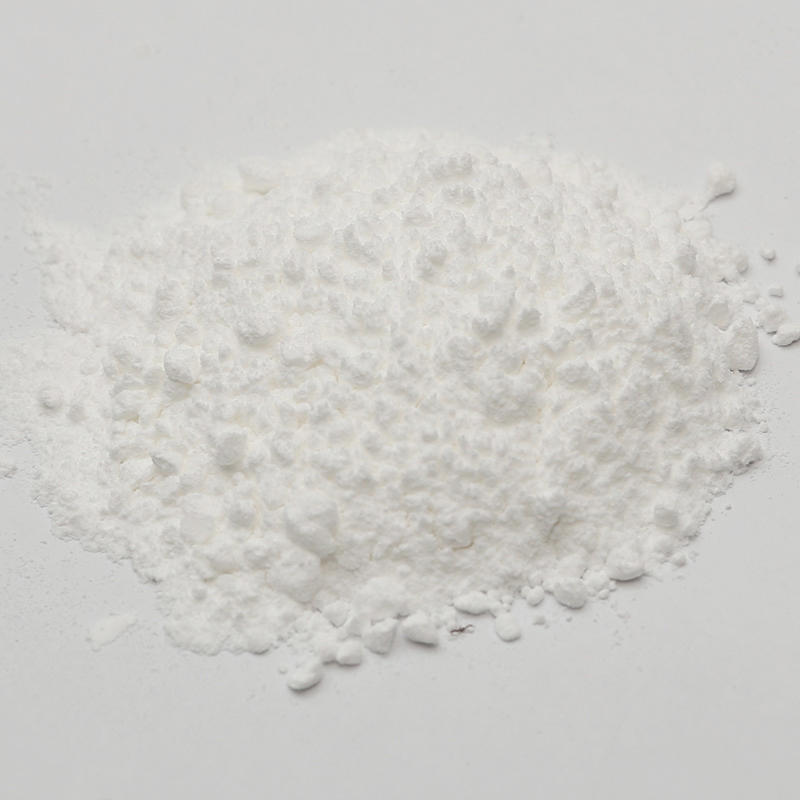

Wholesale Cheap Rubber Vulcanizing Vulcanising Agent Price

Rubber, a versatile and indispensable material in modern industry, owes much of its utility to a process known as vulcanization. This process, which involves the cross-linking of polymer chains, is essential for transforming raw rubber into a durable and stable material. At the heart of vulcanization lies the Vulcanizing Agent, a substance that catalyzes the reaction, thereby enhancing the properties of rubber. This article delves into the pivotal role of Wholesale Vulcanizing Agents in the rubber industry.

Vulcanization is a chemical reaction that has been used for over a century to improve the physical properties of rubber. The process was developed by Charles Goodyear in the 19th century, and it involves the use of a Vulcanizing Agent to facilitate the cross-linking of rubber molecules. This cross-linking is what gives rubber its strength, elasticity, and resistance to heat and chemicals. Without a Vulcanizing Agent, rubber would remain a sticky, weak substance with limited practical applications.

The role of a Vulcanizing Agent is multifaceted. It not only initiates the vulcanization process but also controls the rate at which it occurs. This control is crucial for achieving the desired balance of properties in the rubber product. They can be classified into several types, including sulfur-based, peroxide-based, and metal-based agents. Each type has its own unique characteristics and is chosen based on the specific requirements of the rubber product being manufactured.

Sulfur is the commonly used Vulcanizing Agent due to its effectiveness and cost efficiency. When sulfur is added to rubber, it reacts with the rubber molecules to form cross-links, which are essentially bridges between the polymer chains. These cross-links give the rubber its strength and durability. The amount of sulfur used can be adjusted to achieve different levels of hardness and flexibility in the rubber.

Peroxide-based Vulcanizing Agents, on the other hand, are used when a higher level of heat resistance is required. They work by breaking down into free radicals, which then react with the rubber molecules to form cross-links. This method of vulcanization is known as peroxide curing and is particularly useful for rubber products that will be exposed to high temperatures.

Metal-based Cheap Rubber Vulcanizing Agents, such as those containing zinc or magnesium, are used in specialized applications where the rubber must have exceptional resistance to chemicals or oils. These agents can also impart other desirable properties to the rubber, such as improved adhesion or resistance to aging.

The selection of the appropriate Vulcanizing Agent is critical to the success of the vulcanization process. Factors such as the type of rubber being used, the desired properties of the product, and the specific application for which the rubber is intended all play a role in determining the one to use.

Once the Vulcanizing Agent is chosen and added to the rubber, the mixture is then subjected to heat and pressure. This causes it to activate and begin the cross-linking process. The duration and intensity of the heat and pressure applied can also influence the properties of the rubber, with higher temperatures and longer times generally resulting in a more highly cross-linked and durable product.

The impact of Vulcanising Agent Prices on the rubber industry cannot be overstated. They are the key to unlocking the full potential of rubber, transforming it from a simple, natural material into a complex, high-performance product. Without them, rubber would not be the reliable and versatile material that we rely on in countless applications, from tires and seals to hoses and gaskets.

In conclusion, the role of Vulcanizing Agents in enhancing rubber properties is fundamental to the rubber industry. They are the catalysts that enable the transformation of raw rubber into a material with a wide range of applications. As the demand for rubber products continues to grow, so too does the importance of Vulcanizing Agents in ensuring that these products meet the high standards of performance and durability required in today's world.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体