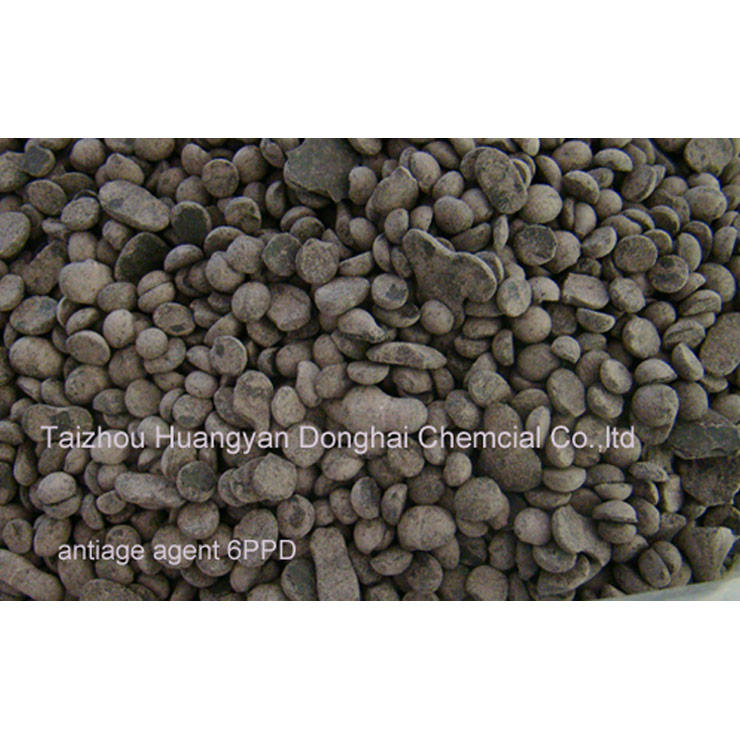

Custom OEM Adhesive Latex Bonding Agent Construction in China

In the realm of manufacturing and design, adhesive agents have become indispensable tools for joining materials together. The use of adhesives has revolutionized the way products are assembled, offering a versatile and efficient alternative to traditional fastening methods. This article delves into the impact of Custom Adhesive Agent,s on product assembly and design, exploring their benefits, challenges, and the innovative ways they are being utilized in various industries.

Adhesive agents are substances that cause two surfaces to bond together by adhering to them. They are used in a wide range of applications, from automotive and aerospace to electronics and consumer goods. The primary advantage of using them is their ability to create strong, durable bonds without the need for mechanical fasteners such as screws, nails, or rivets. This not only simplifies the assembly process but also reduces the overall weight of the product, which is particularly beneficial in industries where weight reduction is crucial.

Benefits of Adhesive Agents. They can provide strong bonds that are often stronger than the materials they join, ensuring the longevity of the product. They can be used to bond a variety of materials, including metals, plastics, glass, and ceramics. Adhesives allow for seamless joins, which can be particularly important in products where appearance is a key factor. The use of them can reduce production costs by eliminating the need for additional fastening components and machinery. Designers can create more complex and innovative designs, knowing that adhesive agents can handle the structural demands.

Despite their numerous advantages, OEM Bonding Agent Constructions also present certain challenges that must be considered. Some adhesives require a significant amount of time to cure, which can slow down production processes. Adhesives can be affected by temperature changes, which may impact their performance in different environments. It is crucial to ensure that they are compatible with the materials being bonded to avoid adverse reactions. The disposal and environmental impact of adhesive agents must be considered, especially in industries with strict environmental regulations.

The use of adhesive agents has led to innovative approaches in product assembly and design. These are used in applications where high strength is required, such as in the automotive and aerospace industries. They are used in products like tapes and labels, offering a quick and easy bonding solution. These are used in electronics to create electrical connections, reducing the need for soldering. They are essential in high-temperature environments, such as engines or exhaust systems.

To better understand the impact of adhesive agents, let's consider a few case studies: Adhesive agents are used extensively in car manufacturing to bond body panels, windshields, and interior components, enhancing both the strength and aesthetics of the vehicle. In this industry, They are critical for joining composite materials, which are lighter and stronger than traditional metals, contributing to fuel efficiency and performance. Adhesive agents are used to secure components in place, protect against shock and vibration, and even create conductive pathways.

As technology advances, so too does the development of Latex Bonding Agent in China. Researchers are continually working on new formulations that offer improved performance characteristics, such as faster curing times, greater temperature resistance, and enhanced environmental sustainability.

The impact of adhesive agents on product assembly and design cannot be overstated. They have transformed the way products are made, offering numerous benefits while also presenting challenges that must be carefully managed. As industries continue to evolve, the role will only grow in importance, driving innovation and enabling the creation of more efficient, durable, and aesthetically pleasing products. The future of adhesive agents looks bright, with ongoing research and development promising even more advanced and specialized adhesive solutions for the industries of tomorrow.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体