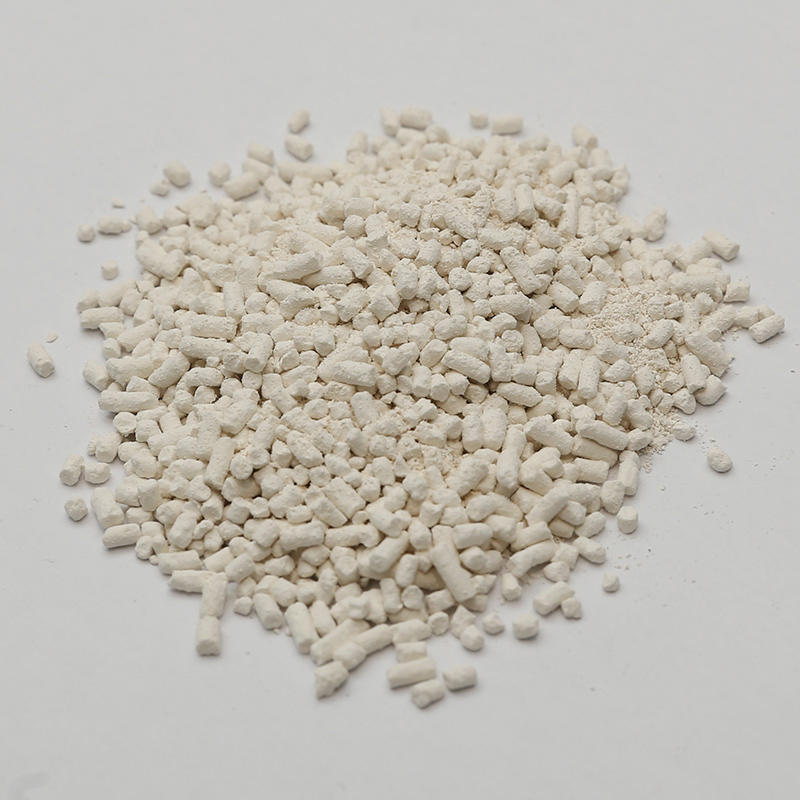

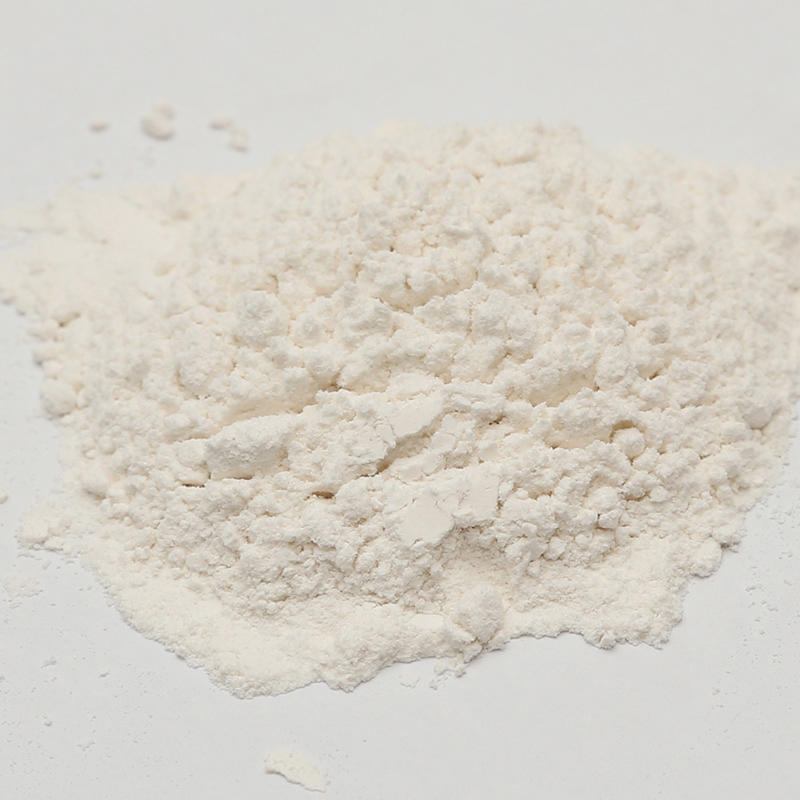

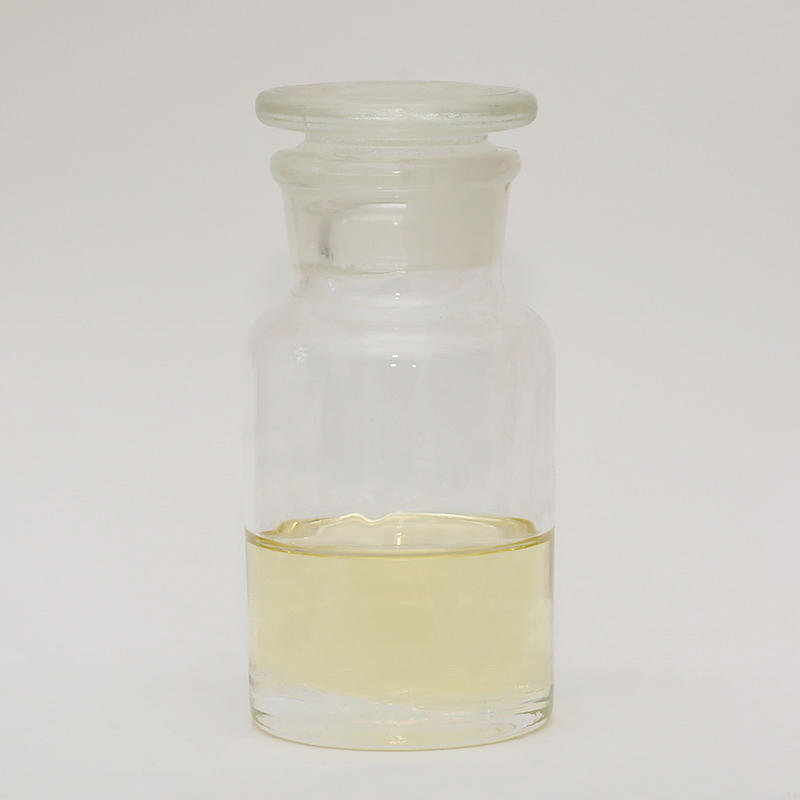

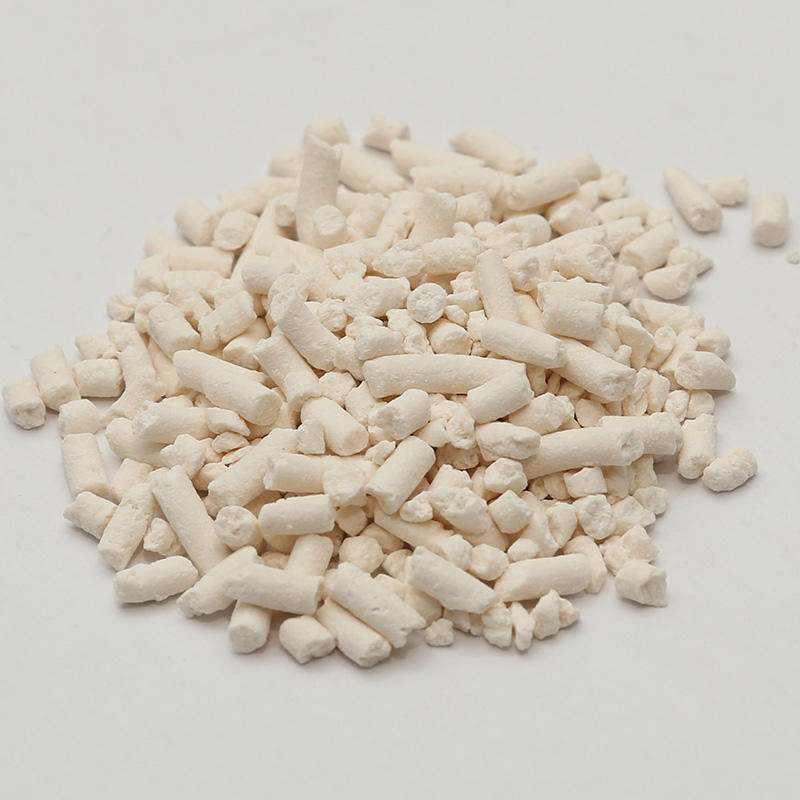

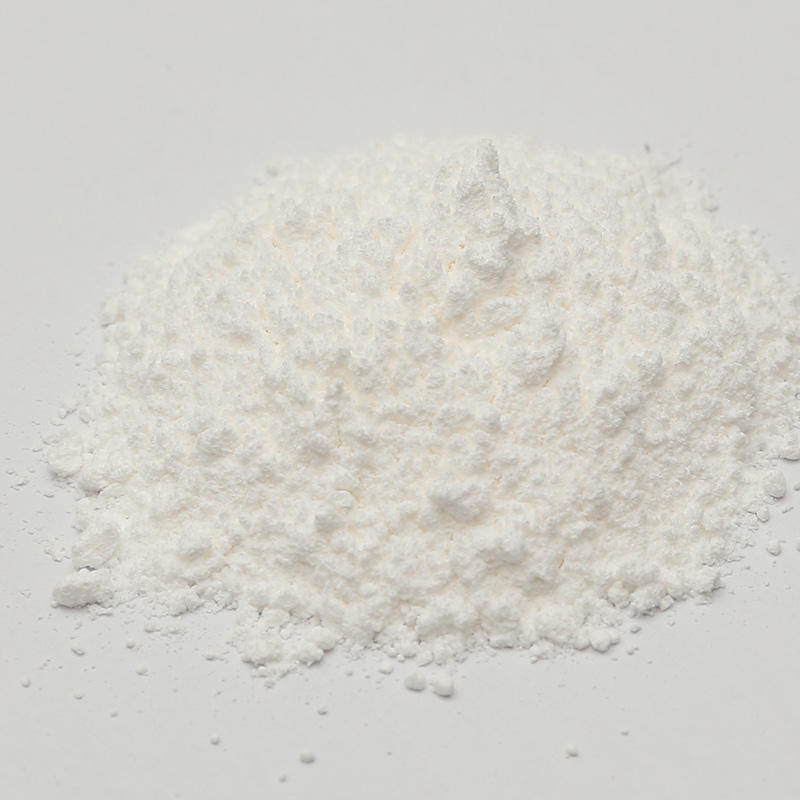

In the realm of industrial rubber manufacturing, the MBTS rubber accelerator has emerged as a critical component in enhancing the quality and efficiency of rubber products. MBTS, also known as Dibenzothiazole Disulfide, is renowned for its role in accelerating the vulcanization process of rubber. This chemical compound facilitates the cross-linking of polymer chains within rubber materials, thereby improving crucial properties such as elasticity, tensile strength, and resilience to wear and environmental factors.

MBTS operates primarily as a vulcanization accelerator, promoting the sulfur cross-linking of rubber molecules during the manufacturing process. Vulcanization transforms raw rubber into a more durable and resilient material suitable for a wide range of applications. By enhancing the cross-linking density and uniformity of rubber networks, MBTS accelerates curing times and improves the mechanical properties of finished products.

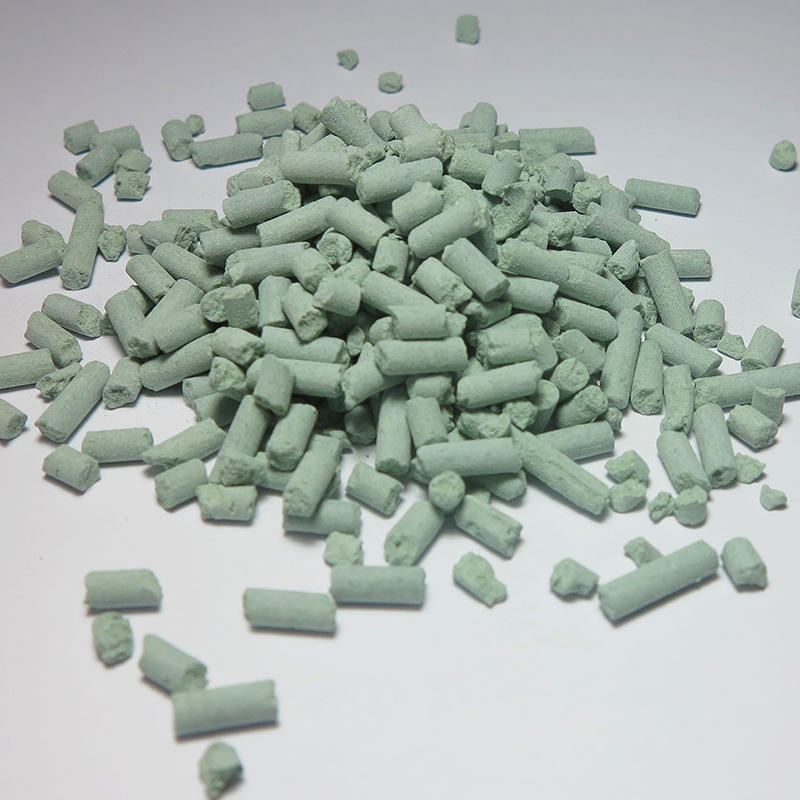

The versatility of MBTS rubber accelerator makes it indispensable across various industries. In the automotive sector, MBTS-treated rubber compounds are extensively utilized in tire manufacturing, contributing to enhanced tread wear resistance, grip performance, and overall durability. Additionally, MBTS-enhanced rubber is crucial for automotive seals, gaskets, and other components requiring resilience to temperature variations and environmental conditions.

Furthermore, MBTS accelerators find applications in industrial rubber goods such as conveyor belts, hoses, and seals, where durability and reliability are paramount. The construction industry benefits from MBTS-treated rubber in roofing membranes, waterproofing materials, and sealants, ensuring longevity and performance in demanding environments.

The integration of MBTS accelerator offers several key benefits that resonate across industrial sectors. Firstly, MBTS significantly reduces the curing time of rubber compounds, thereby optimizing production efficiency and reducing operational costs. Manufacturers can achieve higher throughput and meet stringent production deadlines without compromising on product quality or performance.

Moreover, MBTS-accelerated rubber exhibits mechanical properties, including enhanced tensile strength, tear resistance, and abrasion resistance. These attributes make MBTS-treated rubber ideal for applications requiring resilience to mechanical stress, weathering, and chemical exposure. The robust performance of MBTS-accelerated rubber contributes to extended product lifespan and reduced maintenance requirements, offering long-term cost savings for end-users.

While MBTS accelerates rubber vulcanization effectively, manufacturers and stakeholders prioritize environmental sustainability and safety considerations. Proper handling, storage, and disposal practices are essential to mitigate potential risks associated with chemical substances used in rubber production. Regulatory compliance ensures adherence to environmental regulations and standards governing chemical usage and emissions.

The industry continues to explore sustainable alternatives and eco-friendly formulations that minimize environmental impact throughout the product lifecycle. Research and development efforts focus on improving the environmental footprint of rubber manufacturing processes while maintaining product performance and reliability.

The global market for rubber accelerators, including MBTS, is poised for growth driven by expanding applications across automotive, construction, and industrial sectors. Emerging economies' industrialization and infrastructure development initiatives fuel demand for high-performance rubber materials that can withstand diverse operating conditions.

Looking ahead, technological advancements and innovations in polymer science are expected to drive the evolution of rubber accelerators. Research into novel compounds, formulation techniques, and sustainable manufacturing practices will shape the future landscape of rubber technology. These advancements aim to enhance product performance, optimize production efficiency, and address evolving regulatory requirements, reinforcing MBTS as a cornerstone of modern rubber manufacturing.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体