In a groundbreaking development for the rubber industry, the TMTM TBBS rubber accelerator has emerged as a pivotal catalyst in the production of high-performance tires. This innovative accelerator, touted for its efficiency and sustainability benefits, marks a significant leap forward in tire manufacturing technology. Its integration promises to enhance the durability, safety, and eco-friendliness of tires worldwide.

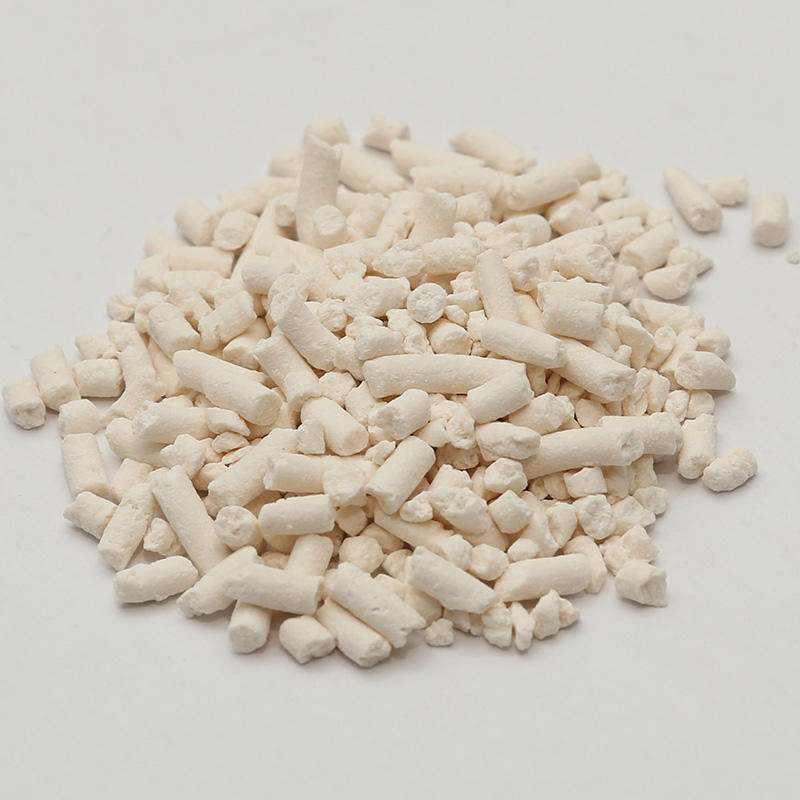

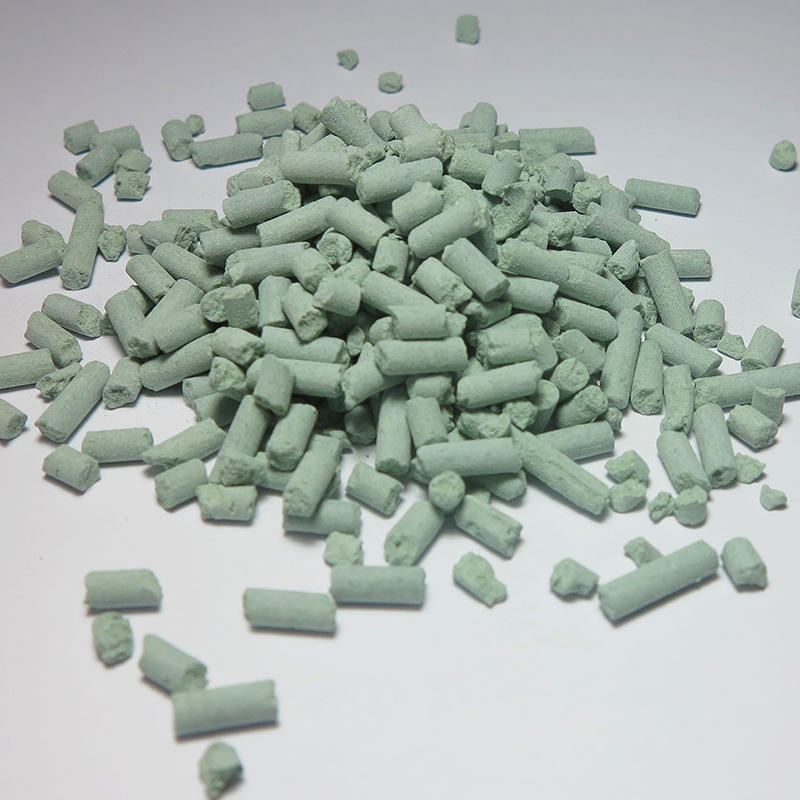

The TMTM TBBS rubber accelerator, a product of intensive research and development, exemplifies cutting-edge chemical engineering at its finest. This accelerator, named after its active ingredients Tetramethylthiuram Monosulfide (TMTM) and N-tert-butyl-2-benzothiazolesulfenamide (TBBS), functions by hastening the vulcanization process of rubber. Vulcanization, a chemical process discovered by Charles Goodyear in the 19th century, involves the cross-linking of rubber molecules to improve elasticity and strength.

Industry experts laud the TMTM TBBS accelerator for its ability to significantly reduce curing time without compromising on the quality of the final product. This acceleration not only streamlines manufacturing processes but also optimizes energy consumption, making it a cost-effective solution for tire producers worldwide. Moreover, its environmental footprint is minimized due to reduced energy usage, aligning with global sustainability goals.

"Integrating TMTM TBBS into our manufacturing process has been transformative," states Dr. Emily Chen, Chief Engineer at a tire manufacturing facility in Asia. "We've observed a marked increase in production efficiency, allowing us to meet growing market demands while maintaining our commitment to sustainability."

The adoption of TMTM TBBS is not limited to large-scale manufacturers; small and medium-sized enterprises are also benefiting from its versatility and performance-enhancing capabilities. This democratization of advanced rubber technology fosters innovation across the industry, promising safer and more durable tires for diverse applications ranging from passenger vehicles to heavy-duty trucks.

Amidst growing demand for eco-friendly products, the TMTM TBBS accelerator stands out for its role in reducing the environmental impact of tire production. By expediting vulcanization and optimizing resource usage, it contributes to lower emissions and waste, thereby supporting sustainable manufacturing practices.

"Customers today are increasingly conscious of the environmental impact of their purchases," notes John Smith, Marketing Director of a tire distributor in Europe. "Products made using TMTM TBBS not only meet stringent quality standards but also align with our commitment to environmental stewardship."

Looking ahead, the future of tire manufacturing appears increasingly intertwined with advanced accelerators like TMTM TBBS. Ongoing research aims to further refine its formulation and explore additional applications in the automotive and industrial sectors. Innovations in chemical engineering continue to pave the way for enhanced product performance, durability, and safety.

As global transportation demands evolve, the tire industry remains at the forefront of technological innovation. The integration of TMTM TBBS into production processes represents a pivotal step towards meeting these demands sustainably and efficiently. With its widespread adoption and positive industry reception, this accelerator is poised to redefine standards for tire quality and performance worldwide.

In conclusion, the emergence of TMTM TBBS as a game-changing accelerator in tire manufacturing underscores the industry's commitment to innovation and sustainability. Its impact extends beyond enhancing production efficiency to encompass environmental responsibility, making it a catalyst for the future of mobility. As research and development continue to drive progress, the tire industry looks towards a future where advanced materials and processes redefine what is possible on the road ahead.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体