Custom OEM Chemical Vulcanizing Materials Agent in China

The world of polymer chemistry is a complex and fascinating realm where the properties of materials can be significantly altered through various processes. One such process is vulcanization, which is pivotal in the rubber industry. At the core of this transformation is the Vulcanizing Agent, a chemical compound that initiates and controls the cross-linking of rubber molecules, thereby enhancing their physical properties. This article aims to shed light on the chemistry behind Custom Vulcanizing Agents and their crucial role in the production of rubber goods.

Vulcanization is a chemical reaction that involves the introduction of cross-links between the long chains of polymers in rubber, which are typically composed of isoprene units. This process was discovered by Charles Goodyear in the 19th century and has since been refined to meet the diverse needs of modern industries. The Vulcanizing Agent plays a central role in this process, acting as a catalyst to facilitate the formation of these cross-links.

The term "Vulcanizing Agent" encompasses a variety of chemicals, with the common being sulfur. When sulfur is added to rubber, it reacts with the double bonds in the polymer chains, creating a three-dimensional network of chemical bonds. This network, known as a cross-linked structure, imparts strength, elasticity, and resilience to the rubber, making it suitable for a wide range of applications.

In addition to sulfur, other Vulcanizing Agents include organic peroxides, metal oxides, and even certain organic compounds. Each type of Vulcanizing Agent has its unique characteristics and is chosen based on the specific properties desired in the rubber product. For instance, organic peroxides are often used in the production of rubber goods that require high resistance to heat and oils, as they produce fewer byproducts and result in a cleaner cross-linking process.

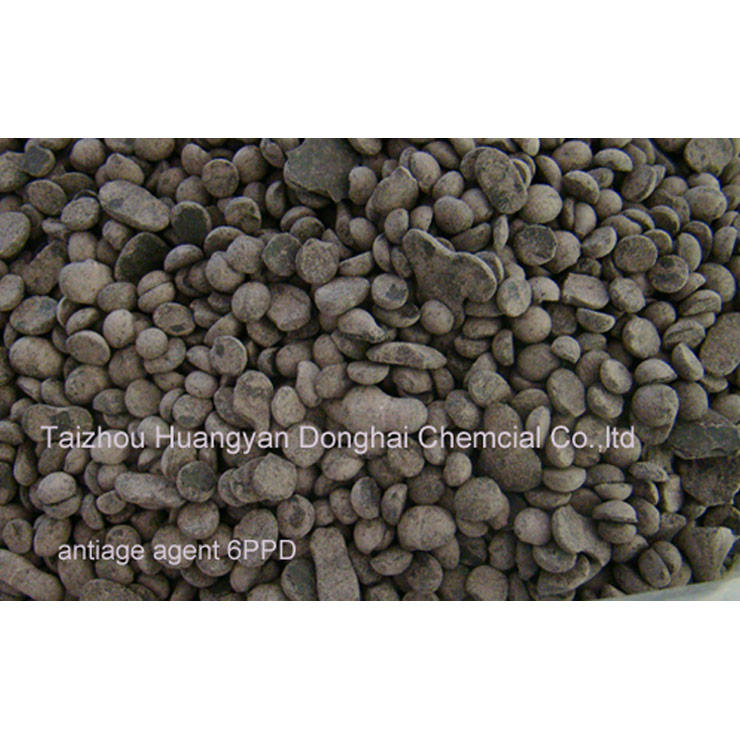

The chemistry of Vulcanizing Agents is not limited to their role in cross-linking. They also play a significant role in influencing other properties of rubber, such as its resistance to aging, its flexibility, and its resistance to various environmental factors. The selection and use of a particular OEM Chemical Vulcanizing are therefore critical in determining the performance of the rubber product, as it can dictate the material's longevity, durability, and overall utility in diverse applications.

The process of vulcanization is indeed influenced by a multitude of factors, including temperature, pressure, and the presence of accelerators. These accelerators are crucial chemicals that not only increase the rate of the vulcanization reaction but also enable it to proceed more rapidly and at lower temperatures, which is particularly advantageous in industrial settings. The efficiency and cost-effectiveness of the vulcanization process are paramount in these environments, where large-scale production and quick turnaround times are essential. The judicious use of accelerators can significantly reduce energy consumption and production times, making the process more sustainable and economically viable.

The development of new Vulcanizing Agents is an ongoing area of research in materials science. As new rubber applications emerge, such as in the automotive, aerospace, and medical industries, the need for rubber with specific properties becomes more critical. Scientists are continually exploring new compounds and formulations to meet these evolving demands.

In conclusion, the chemistry behind Chemical Vulcanizing in China is a complex and dynamic field that plays a vital role in the rubber industry. From the traditional use of sulfur to the cutting-edge development of new agents, the quest to enhance the properties of rubber is driven by the innovative application of chemical principles. Understanding the role of Vulcanizing Agents is essential for anyone involved in the production, research, or application of rubber goods, as it is these agents that unlock the full potential of this versatile material.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体