In the dynamic landscape of the manufacturing industry, the quest for more efficient, sustainable, and innovative materials continues to drive significant advancements. One such breakthrough is the application of TMTM rubber accelerator, a chemical compound that is transforming rubber production and enhancing the properties of various rubber products. This compound is not only improving the quality and performance of rubber goods but also contributing to more sustainable manufacturing practices.

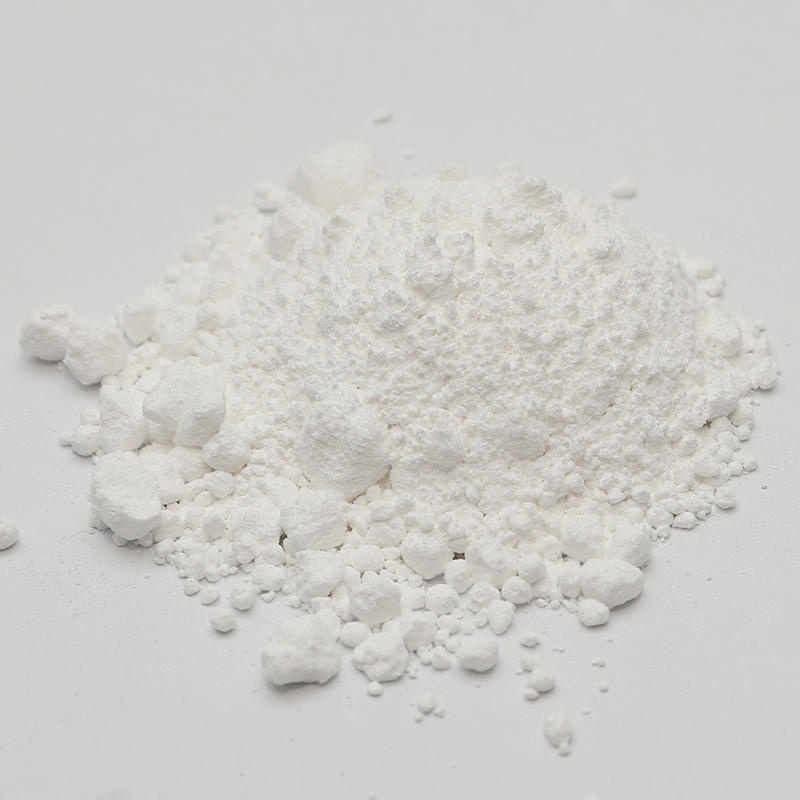

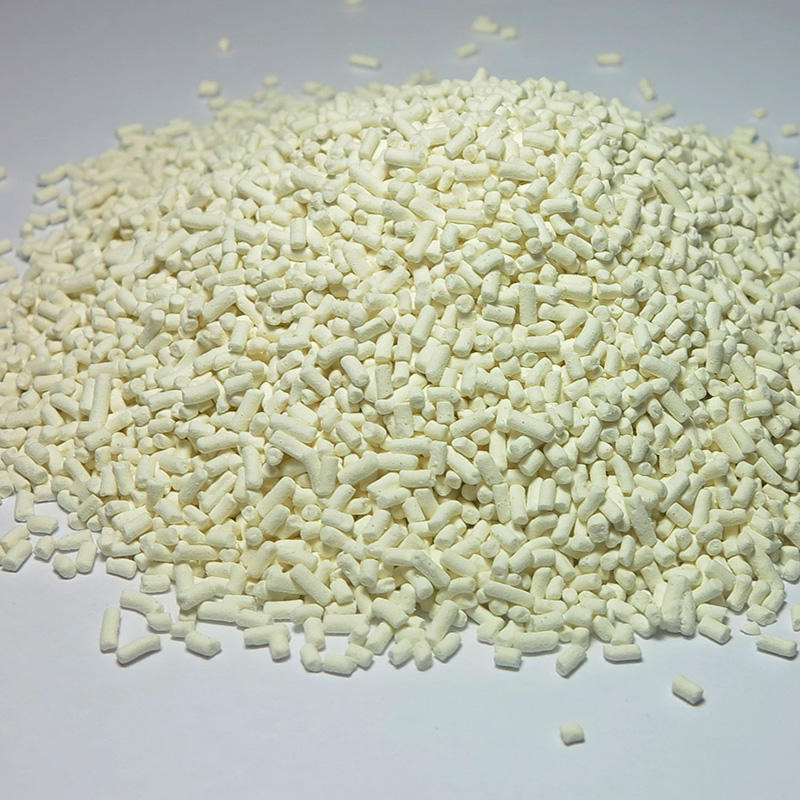

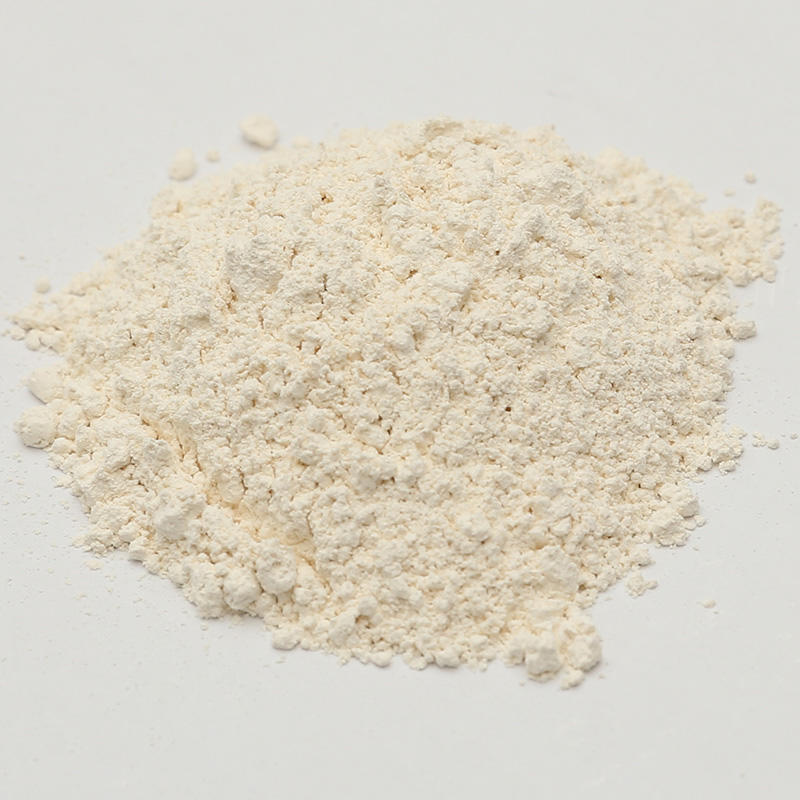

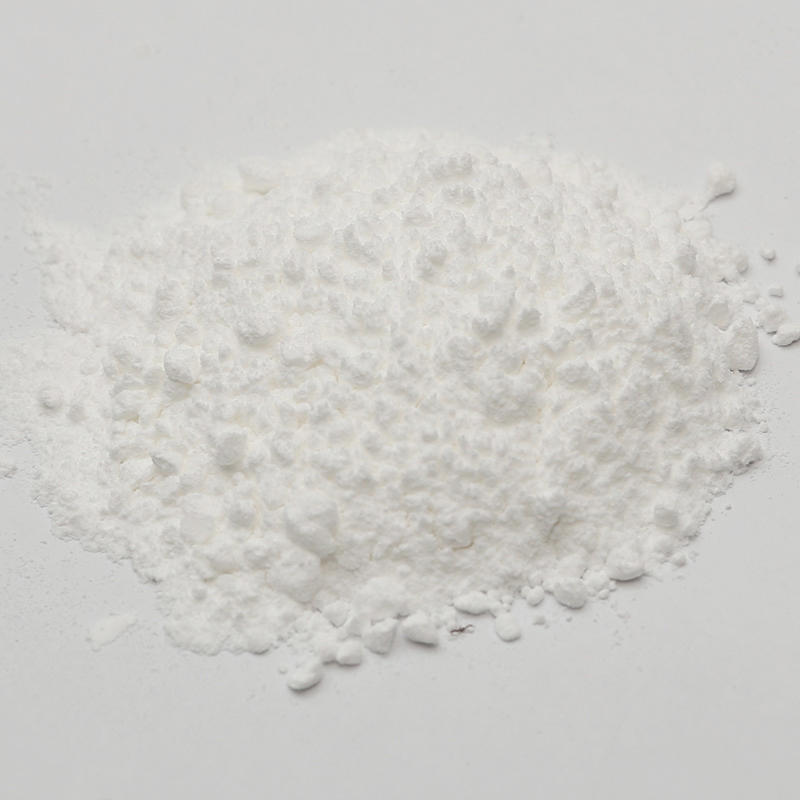

TMTM, or Tetramethylthiuram Monosulfide, is a versatile rubber accelerator widely used in the vulcanization process. Vulcanization is a chemical process that strengthens rubber by forming cross-links between polymer chains, significantly enhancing its durability, elasticity, and resistance to various environmental factors. The use of TMTM rubber accelerator in this process results in rubber products that meet the demanding requirements of modern applications.

One of the primary benefits of TMTM rubber accelerator is its efficiency in speeding up the vulcanization process. Traditional vulcanization methods can be time-consuming and energy-intensive, but with TMTM rubber accelerator, the process is considerably faster and more efficient. This increased efficiency translates to reduced production times and lower energy consumption, making it an attractive option for manufacturers looking to optimize their operations and reduce costs.

In addition to its efficiency, TMTM rubber accelerator offers performance characteristics. Rubber products treated with TMTM exhibit enhanced mechanical properties, such as increased tensile strength, improved elasticity, and greater resistance to wear and tear. These qualities are essential for a wide range of applications, from automotive components and industrial machinery to consumer goods and medical devices. The durability and reliability of TMTM-accelerated rubber ensure that products can withstand rigorous use and harsh conditions, providing long-lasting performance.

The automotive industry, in particular, has benefited significantly from the use of TMTM rubber accelerator. Tires, seals, hoses, and various other components rely on high-quality rubber to ensure safety and functionality. The properties of TMTM-accelerated rubber contribute to the production of automotive parts that are not only durable but also capable of maintaining performance under conditions. This reliability is crucial for the safety and efficiency of vehicles, highlighting the importance of advanced materials in automotive manufacturing.

Another critical advantage of TMTM rubber accelerator is its role in promoting sustainability. As the world increasingly prioritizes environmental responsibility, the demand for eco-friendly manufacturing processes and materials is growing. TMTM rubber accelerator contributes to this goal by enabling more efficient production methods that consume less energy and generate fewer emissions. Moreover, the enhanced durability of TMTM-accelerated rubber products means they have a longer lifespan, reducing the frequency of replacement and minimizing waste.

The medical industry also benefits from the application of TMTM rubber accelerator. Medical devices and equipment, such as gloves, tubing, and seals, require rubber materials that are not only safe and reliable but also capable of withstanding sterilization processes and frequent use. The improved properties of TMTM-accelerated rubber ensure that medical products meet stringent quality and safety standards, providing healthcare professionals with the tools they need to deliver effective patient care.

Technological advancements in the production and application of TMTM rubber accelerator are continually driving innovation. Researchers and manufacturers are exploring new formulations and techniques to further enhance the performance and sustainability of TMTM-accelerated rubber. These efforts are to the development of rubber products that can meet even more specialized requirements, from high-performance athletic gear to advanced aerospace components.

In addition to its technical benefits, the use of TMTM rubber accelerator can also offer economic advantages. The increased efficiency and reduced production costs associated with TMTM make it a cost-effective solution for manufacturers. This economic benefit is particularly important in competitive industries where cost control and product quality are critical to maintaining market position and profitability.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体