In the dynamic realm of rubber manufacturing, two revolutionary chemical compounds are making significant waves—the TMTM and TBBS rubber accelerators. These innovative accelerators are transforming the vulcanization process, enhancing the performance and durability of rubber products across various industries, from automotive to construction.

Firstly, let's delve into the TMTM rubber accelerator. TMTM, short for Tetramethylthiuram Monosulfide, is a sulfur-containing organic compound renowned for its role as an accelerator in the vulcanization process of rubber. This compound offers remarkable benefits, including fast-curing properties that expedite the curing process, leading to shorter vulcanization times and increased operational efficiency. Additionally, it enhances the mechanical properties of rubber compounds, resulting in higher-quality and longer-lasting rubber products.

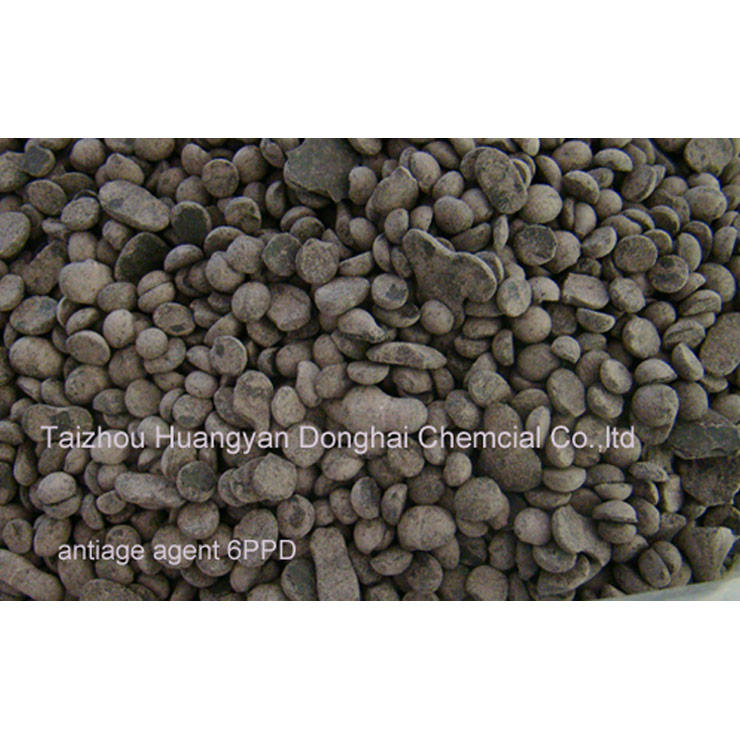

Similarly, the TBBS rubber accelerator, or N-tert-Butyl-2-benzothiazolesulfenamide, is revolutionizing the rubber industry. This compound accelerates the vulcanization process, reducing production costs and enhancing the tensile strength, elongation, and aging resistance of rubber materials. With its rapid-curing attributes and superior mechanical properties, TBBS ensures optimal performance and durability in rubber products across diverse applications.

Industries such as automotive rely heavily on the TMTM and TBBS rubber accelerators to ensure the durability and performance of tires, seals, gaskets, and various other rubber components. Their ability to bolster the mechanical properties of rubber materials ensures optimal functionality, safety, and reliability in demanding applications.

Moreover, the utility of TMTM and TBBS rubber accelerators extends beyond automotive applications, encompassing sectors like construction and industrial manufacturing. In construction, these accelerators play a pivotal role in fabricating high-performance rubber seals, membranes, and adhesives for waterproofing and sealing purposes. Similarly, in industrial manufacturing, they enhance the durability and flexibility of rubber components, contributing to the efficiency and longevity of machinery and equipment.

"The TMTM and TBBS rubber accelerators epitomize versatility and reliability across a spectrum of rubber applications," asserts rubber industry expert Alex. "Their capacity to enhance curing efficiency and mechanical properties renders them indispensable assets in achieving unmatched performance and durability in rubber products."

Beyond their technical prowess, TMTM and TBBS rubber accelerators also boast environmental advantages. Their expedited curing process minimizes energy consumption and greenhouse gas emissions, promoting sustainability and environmental responsibility in the rubber industry. Additionally, their superior mechanical properties translate to prolonged longevity of rubber products, mitigating the need for frequent replacements and minimizing waste.

"As the demand for sustainable and high-performance rubber products surges, TMTM and TBBS rubber accelerators emerge as pivotal forces in driving innovation and advancement in the industry," underscores environmental advocate Emma. "Their fusion of technical excellence and environmental consciousness presents win-win solutions for manufacturers and consumers alike."

From automotive to construction, TMTM and TBBS rubber accelerators are spearheading innovation and setting new benchmarks for performance and durability in the rubber sector. With their swift-curing attributes, enhanced mechanical properties, and environmental benefits, they present compelling solutions for manufacturers seeking to meet evolving market demands while minimizing their ecological footprint.

Thus, whether traversing the roads, walking on rubberized surfaces, or relying on rubber seals and gaskets in industrial settings, consumers are undoubtedly benefiting from the superior performance and longevity of products fortified by TMTM and TBBS rubber accelerators. As the rubber industry continues its evolutionary trajectory, these groundbreaking compounds will remain at the forefront of technological progress, shaping the future of rubber manufacturing for years to come.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体