CAS Number: 17796-82-6

Other names: scorch retarder; early vulcanization inhibitor; anti-scorch agent CTP; anti-scorch agent PVI

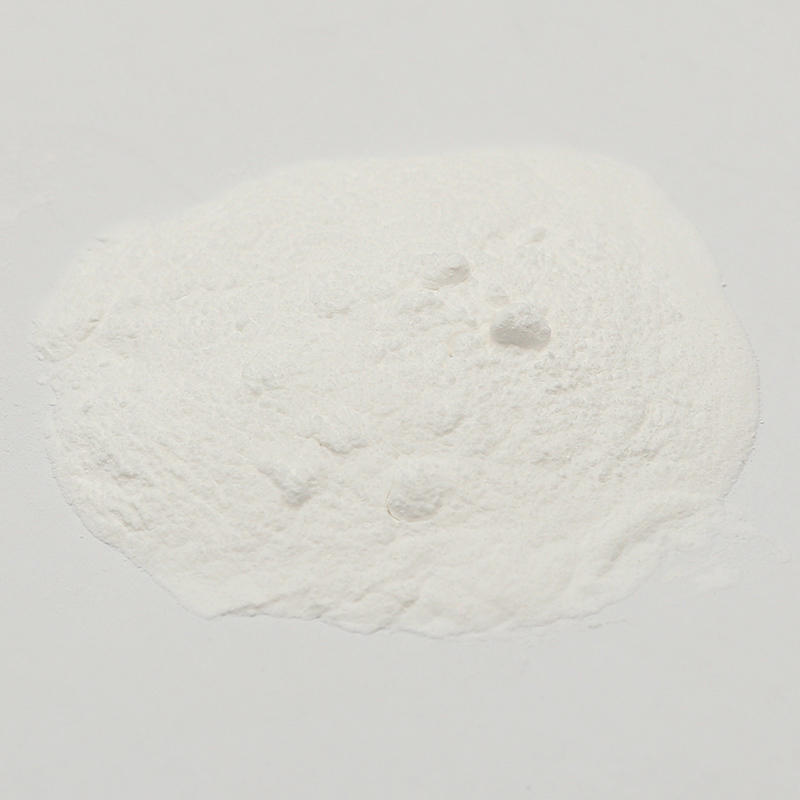

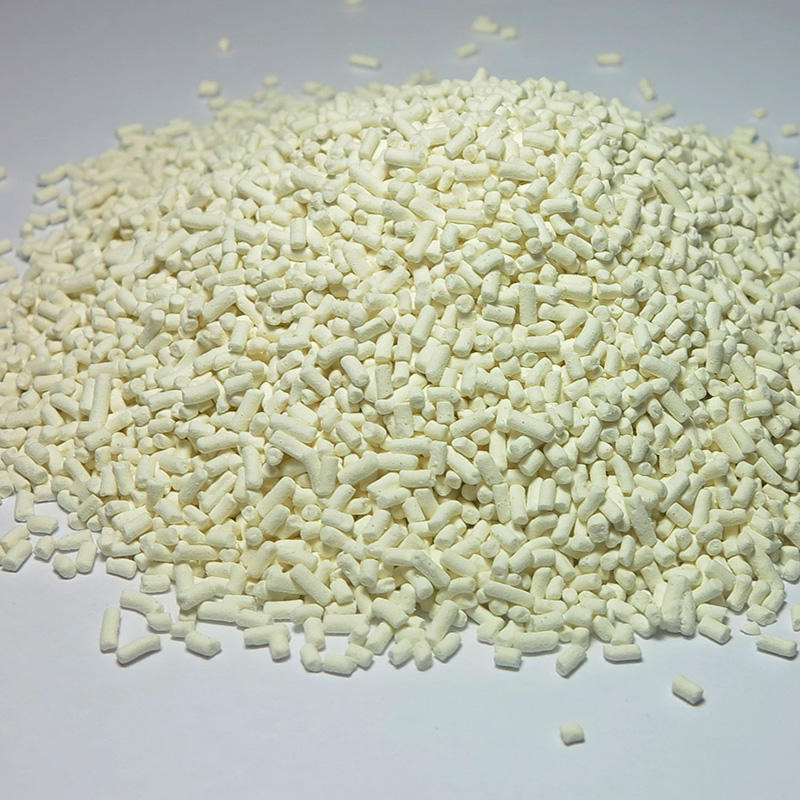

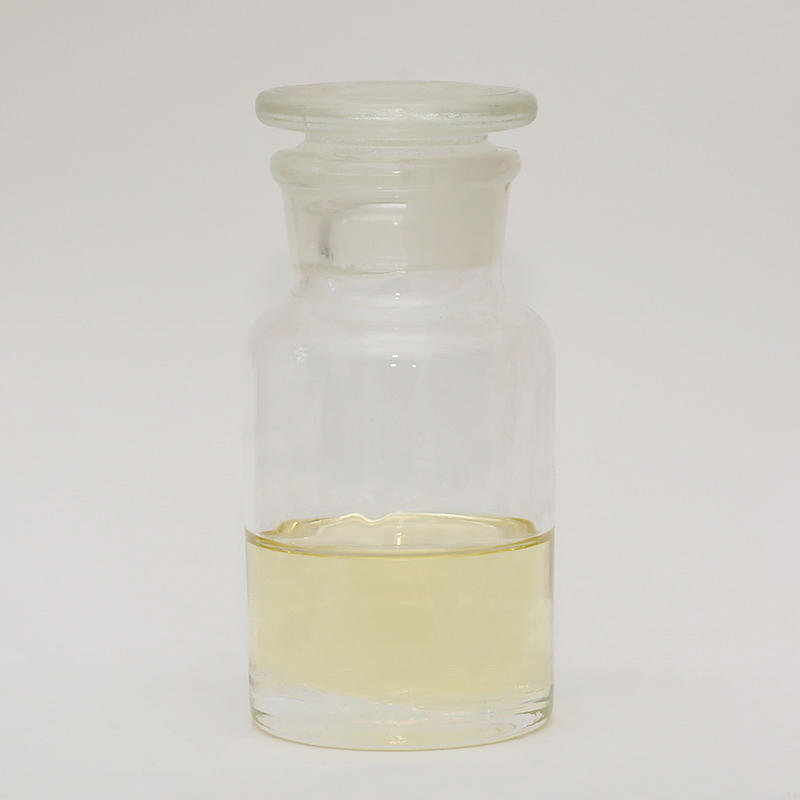

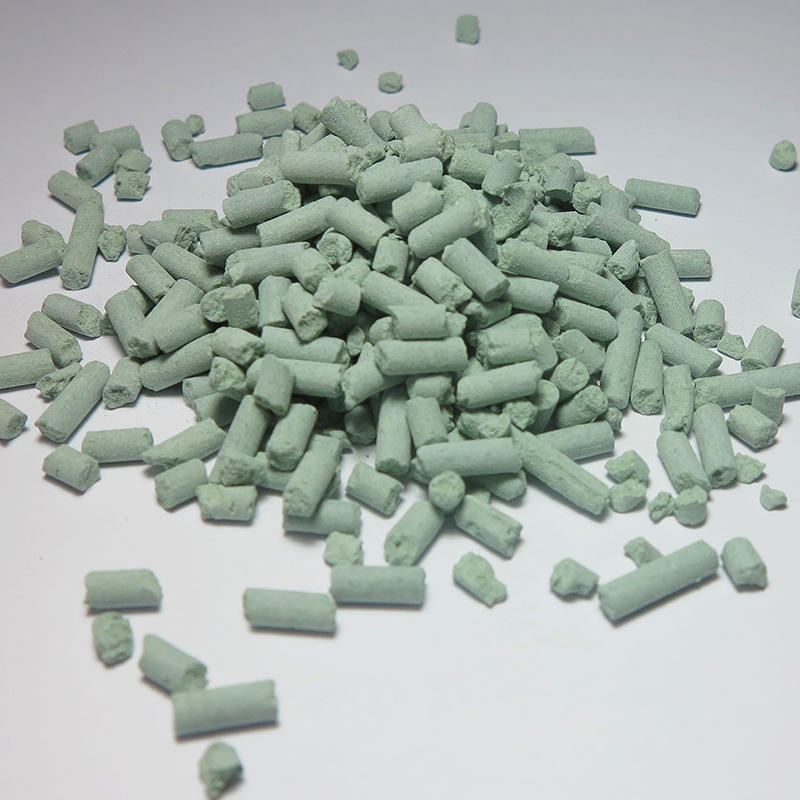

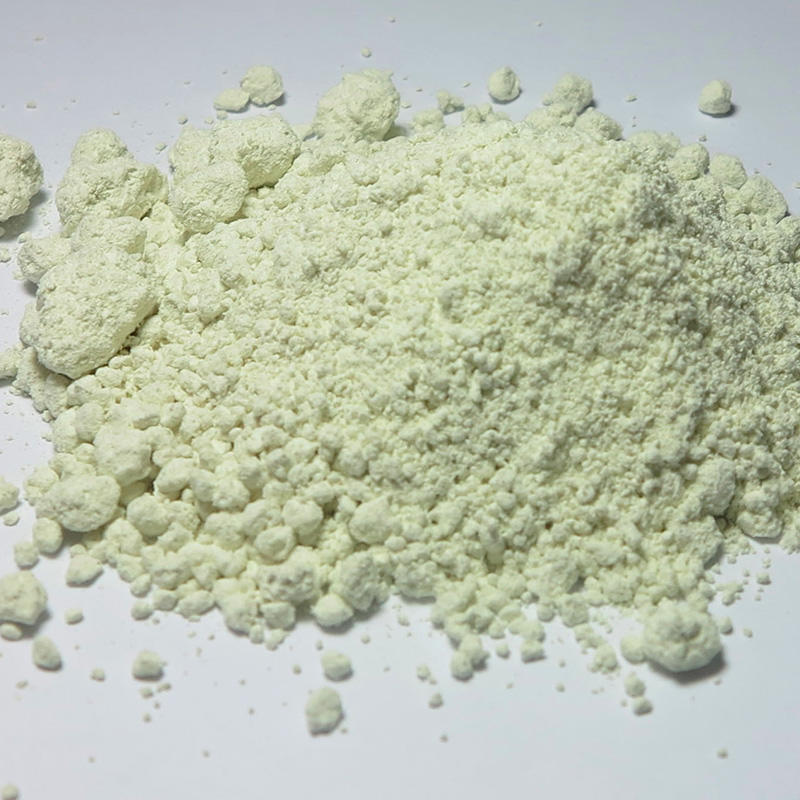

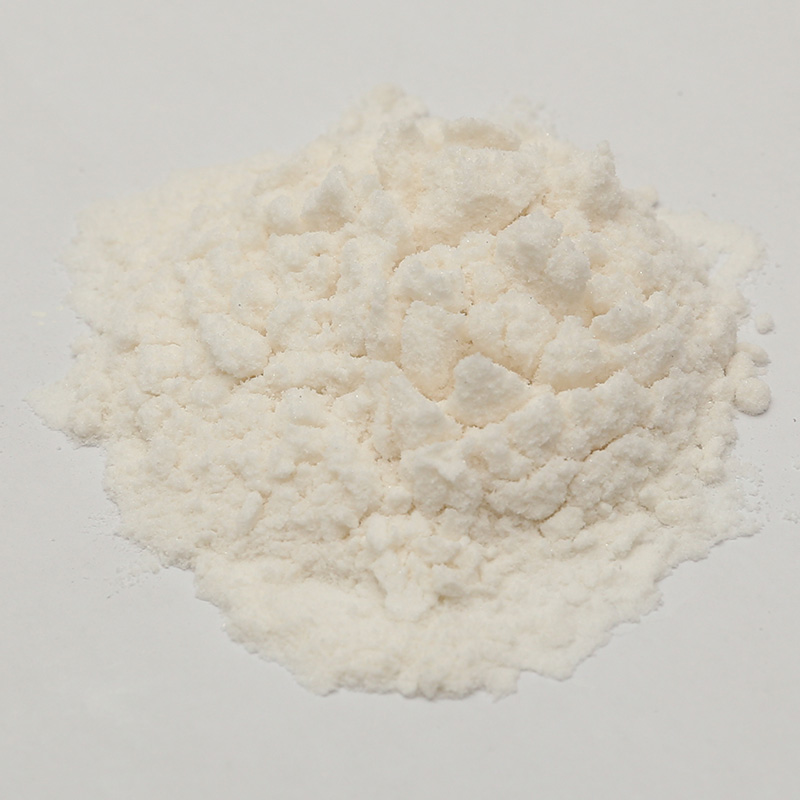

Physical and chemical properties: light yellow-brown crystals. The product recrystallized from n-heptane is white crystals. It is soluble in acetone, benzene, toluene, ether and ethyl acetate, but insoluble in water. It is soluble in hot carbon tetrachloride, ethanol and heptane. Avoid excessively high or low temperature and humidity during storage. Flammable and low toxicity.

Manufacturing method: React cyclohexane with hydrochloric acid to generate chlorinated cyclohexane. Then sulfur is used for sulfurization to prepare chlorothiocyclohexane. Finally, the product is prepared by reacting phthalimide and chlorothiocyclohexane in the presence of an acid absorbent. Application: It can be used for natural rubber and synthetic rubber. It can effectively prevent the rubber from scorching during processing and improve production efficiency. At the same time, it has a restoring effect on the rubber that has been subjected to high heat or slightly scorched.

N-cyclohexylthiophthalimide is widely used in sulfur-vulcanizable elastomers, and it has good anti-scorching effect when used with various general accelerators. With the anti-scorching agent CTP, whether it is open or high-temperature rapid banquet, one stage mixing process can be used to effectively prevent scorching. It can be used with accelerators M, DM, TMTD and effective or semi-effective vulcanization systems to improve rubber performance. Can improve the production efficiency of calendering and pressing. It is beneficial to improve the adhesion between rubber and brass-plated steel wire. It is widely used in various general-purpose rubbers and special rubbers including nitrile rubber, ethylene-propylene or ethylene-propylene rubber, butyl rubber and neoprene. During storage, avoid excessively high or low temperature and humidity, and place in a ventilated and dry place to avoid heat and moisture.

Antiscorch agent CTP(PVI)

USE:

Scorch retarder for synthetic rubber and natural rubber. It can be used in combination with all sulfenamide or thiazole accelerators to control the safety of operation and prevent early vulcanization without affecting the vulcanization characteristics and performance of the vulcanizate. This product can significantly improve the storage stability of unvulcanized rubber and greatly reduce the amount of waste rubber. The dosage is 0.1-0.3 parts. This product does not pollute.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体