1. After the rubber accelerator is added to the rubber compound, it can reduce the vulcanization temperature or shorten the vulcanization time.

2. The accelerator is added to the rubber compound to promote the activation of the vulcanizing agent, thereby accelerating the cross-linking reaction between the vulcanizing agent and the rubber molecules, and achieving the practical effects of shortening the vulcanization time, lowering the vulcanization temperature, increasing the output, and reducing the production cost.

2. What is a rubber accelerator?

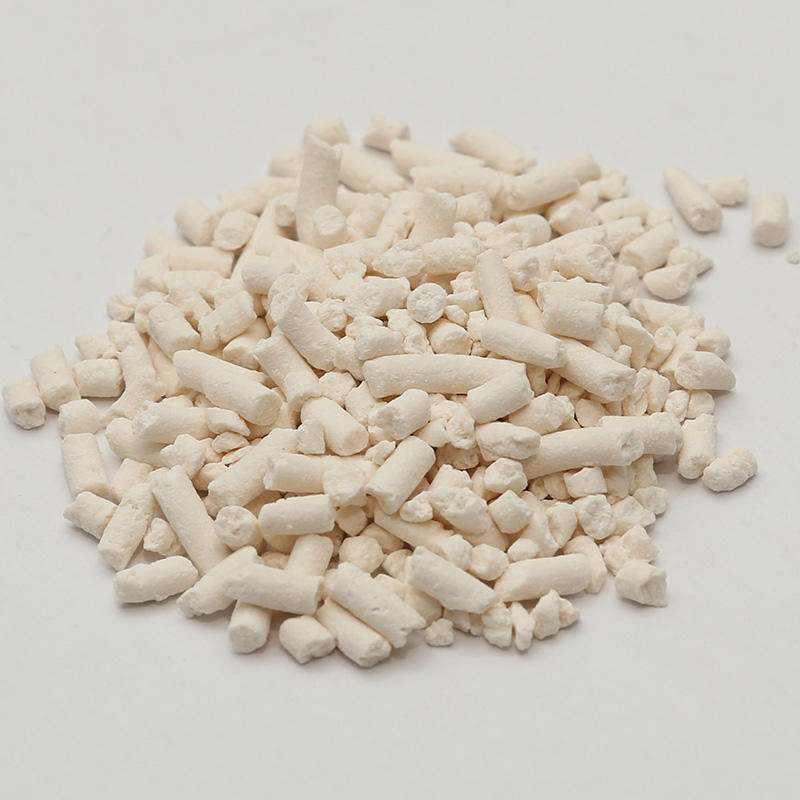

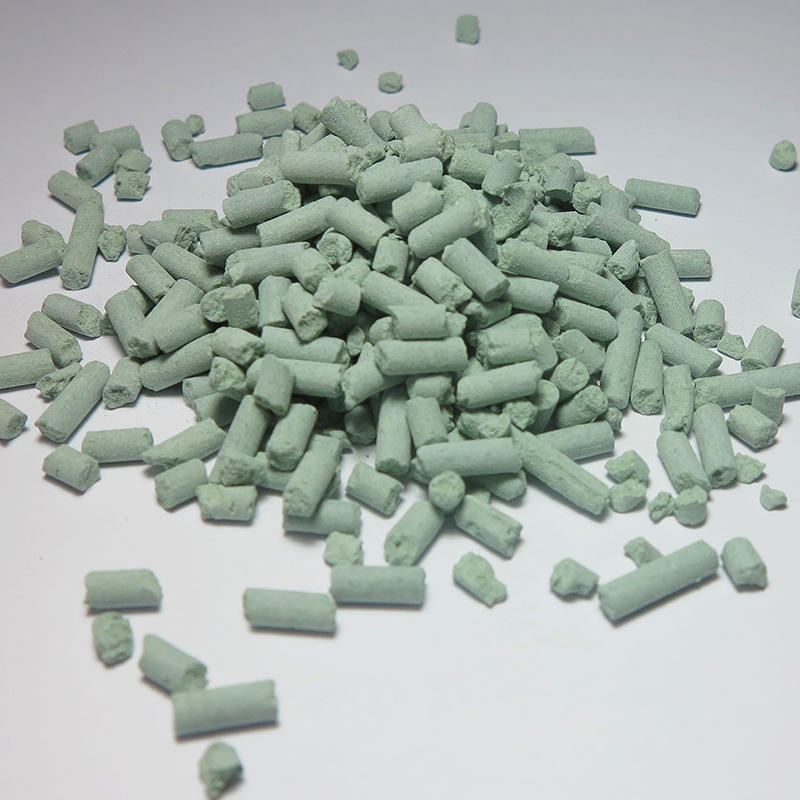

It refers to rubber vulcanization accelerator. Rubber vulcanization is mainly made of sulfur, but the reaction between sulfur and rubber is very slow, so vulcanization accelerators came into being. The accelerator added to the rubber compound can promote the activation of the vulcanizing agent, thereby speeding up the cross-linking reaction between the vulcanizing agent and the rubber molecules, and achieving the effect of shortening the vulcanization time and lowering the vulcanization temperature. The main vulcanization accelerators used are classified into sulfenamides, thiazoles, and thiurams according to their chemical structure, as well as some guanidines, thioureas and dithiocarbamates. Among them, sulfenamides have the best comprehensive performance and the most widely used.

3. What are the benefits of using rubber accelerators?

1. The vulcanization time is shortened and the vulcanization temperature is lowered, which can increase production efficiency and reduce costs.

2. Due to the decrease in the amount of sulfur; the decrease of the vulcanization temperature and the function of some accelerators as antioxidants, the service life of rubber products can be increased.

3. It can improve the physical and mechanical properties of products, especially thick products, and has a good flattening effect in the production of thick products, so that the inside of the product can reach positive vulcanization, and the physical and mechanical properties of the surface of the product will not decrease.

4. Improve the appearance quality of the product. Due to the reduction in the amount of sulfur, it will not be sprayed with sulfur.

4. What problems should be paid attention to when choosing rubber accelerator DM?

1. The selected rubber accelerator DM should be coordinated with the curing agent, not resistant, and have a good match.

2. Effective accelerators should be selected according to different types of adhesives.

3. The selected accelerator should not affect the process performance and physical and mechanical properties of the adhesive.

4. It should be non-toxic or low-toxic, and harmless to the human body and the environment.

5. The addition amount of rubber accelerator DM should be small and the promotion efficiency should be high. It can also be used in a mixture of 2 or more kinds of accelerators, so that they can complement each other's strengths and increase the promotion effect.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体