foams used in the production process of the products. The water brought in by the agent, etc., makes the product without pores, the section is uniform, dense, and the surface is smooth and beautiful. Especially suitable for normal

pressure vulcanized rubber assembly line, it is a must

Physical and chemical properties

product category

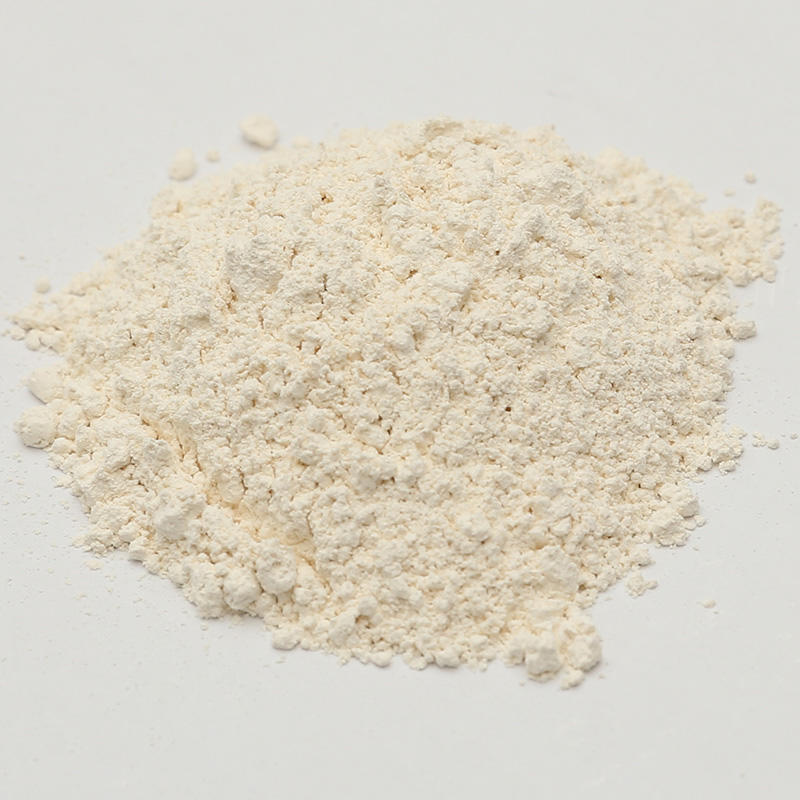

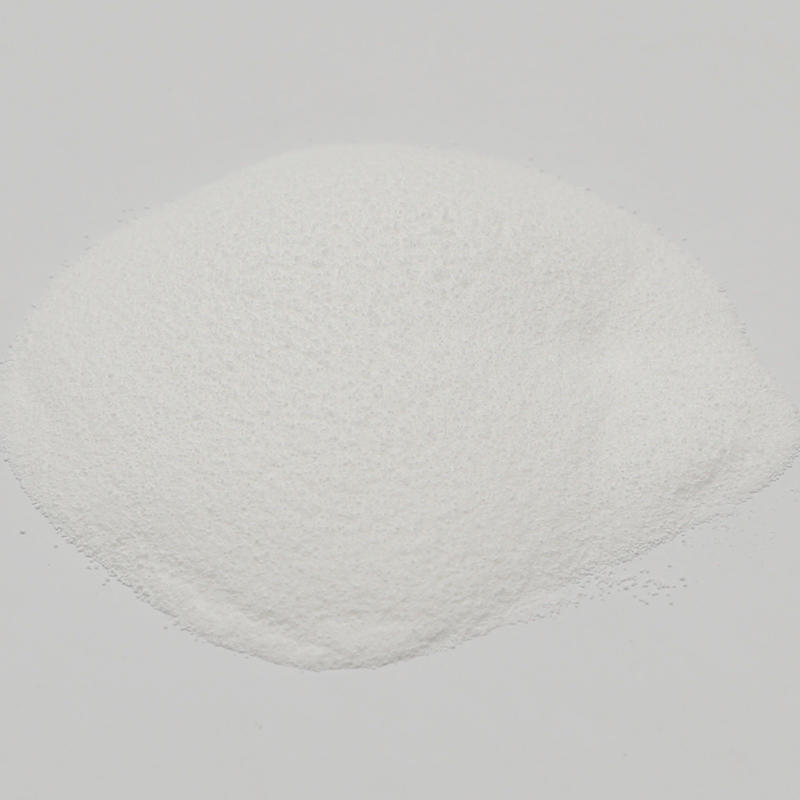

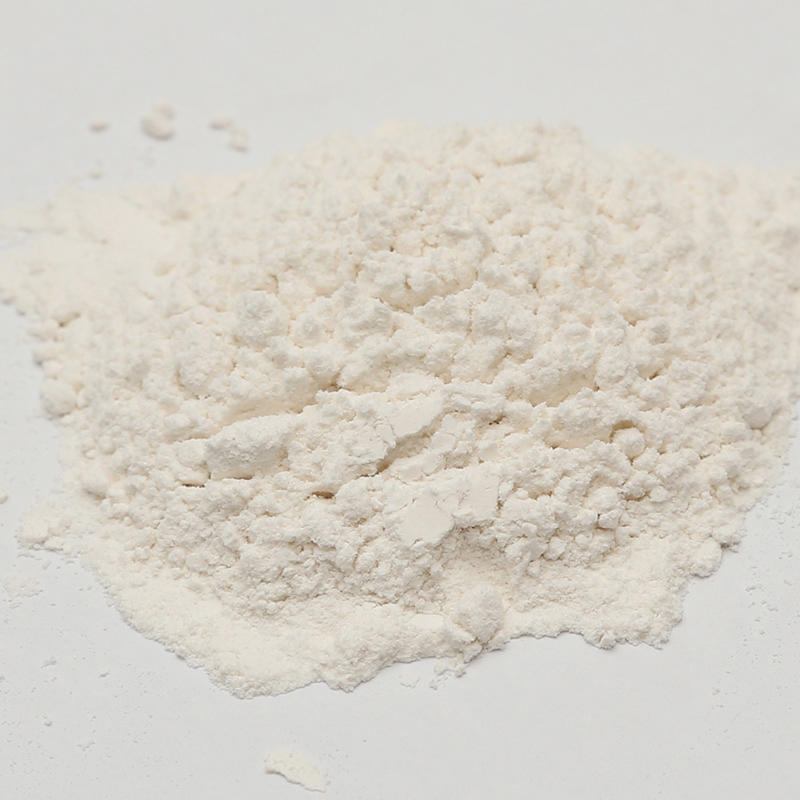

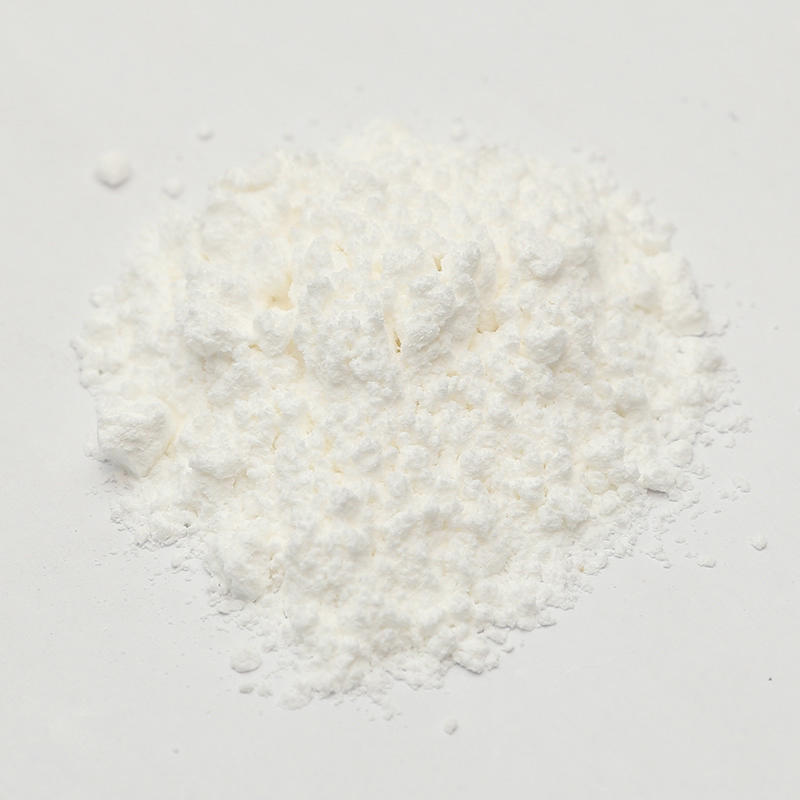

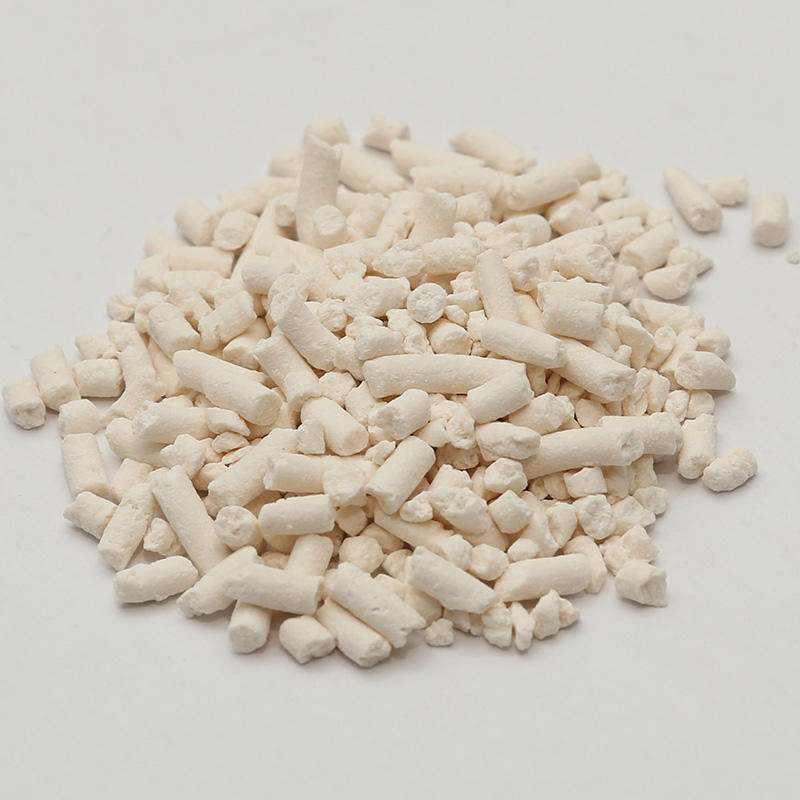

Divided into three types: Ⅰ, Ⅱ, and Ⅲ. Type I defoamer is pure white powder;

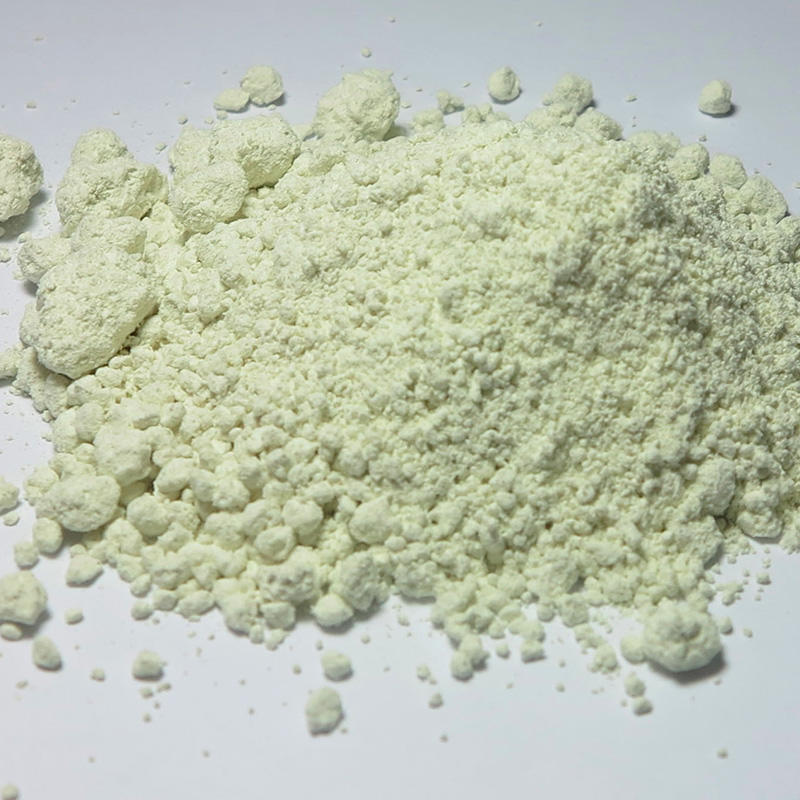

Type Ⅱ defoamer is slightly yellow or white powder;

Type Ⅲ defoamer is light yellow or light gray paste-like solid.

Product ingredients

The main components of the three defoamers are calcium oxide, and they all contain organic matter, which have strong water absorption and produce calcium hydroxide after the reaction.

Product additives

The surface of the particles of the three products are coated with one or more organic substances to form a protective film to passivate and protect the main components to prevent premature hydration. These organics play a role in the

dispersion of rubber to make it evenly dispersed.

Technical index

(Note: The implementation standard for the following indicators is Q/PBH01-2003)

Project Index (%) Index (%) Index (%)

Type Ⅰ Type Ⅱ Type Ⅲ

Sieve residue 45 microns (≤) 0.45 0.45 0.45

Burning weightlessness (≤) 5 22 30

Calcium oxide (calculated on dry basis after burning) (≥) 95 95 95

Packaging, storage and transportation

The packaging companies have different standards. But it should be noted that the product should avoid contact with acid, steam or liquid water, and the packaging should not be damaged. Moisture-proof measures must be taken during

storage and transportation.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体