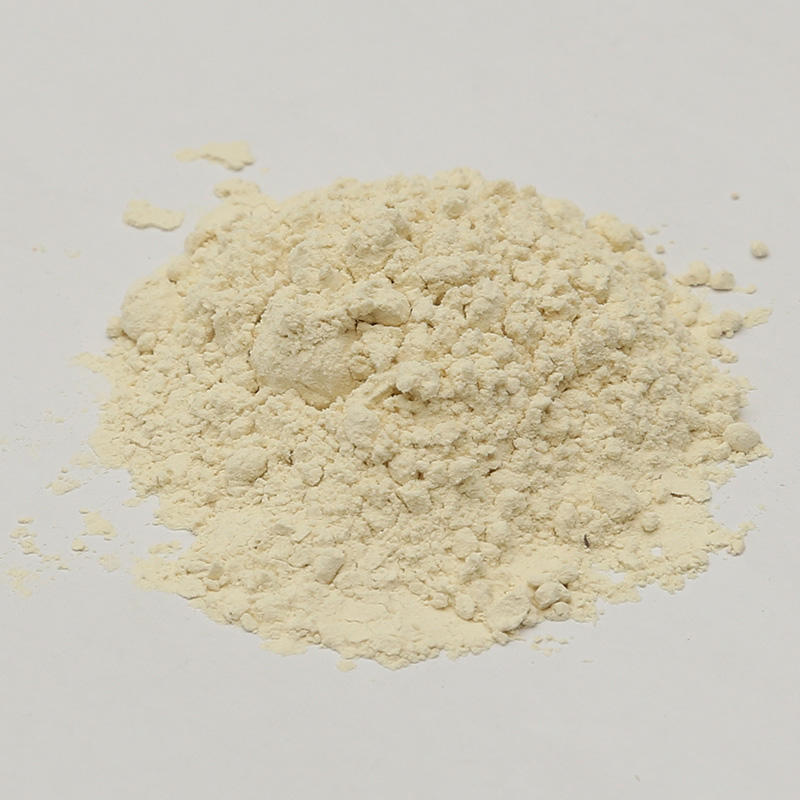

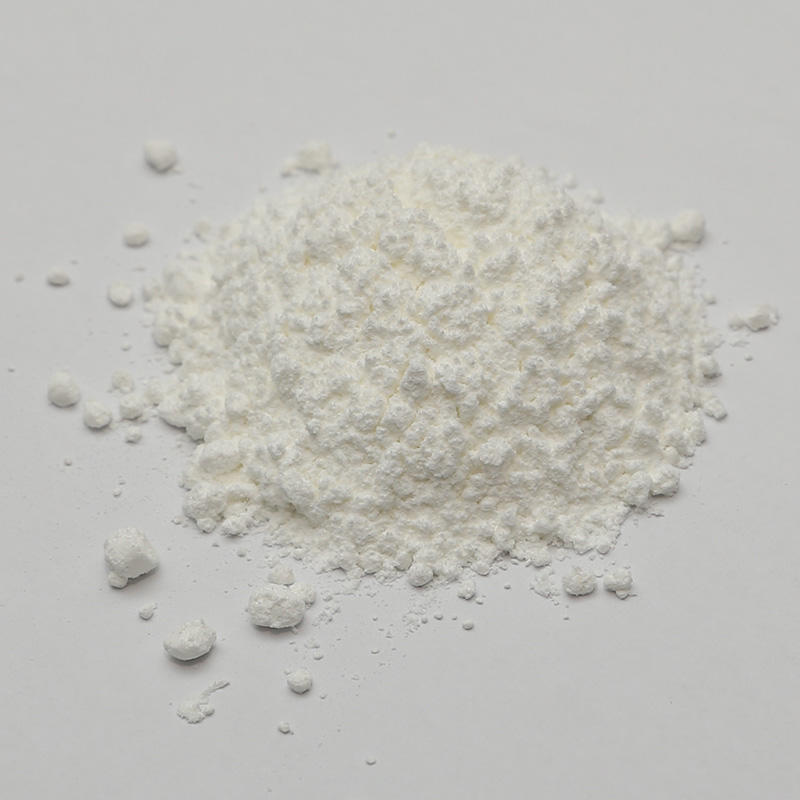

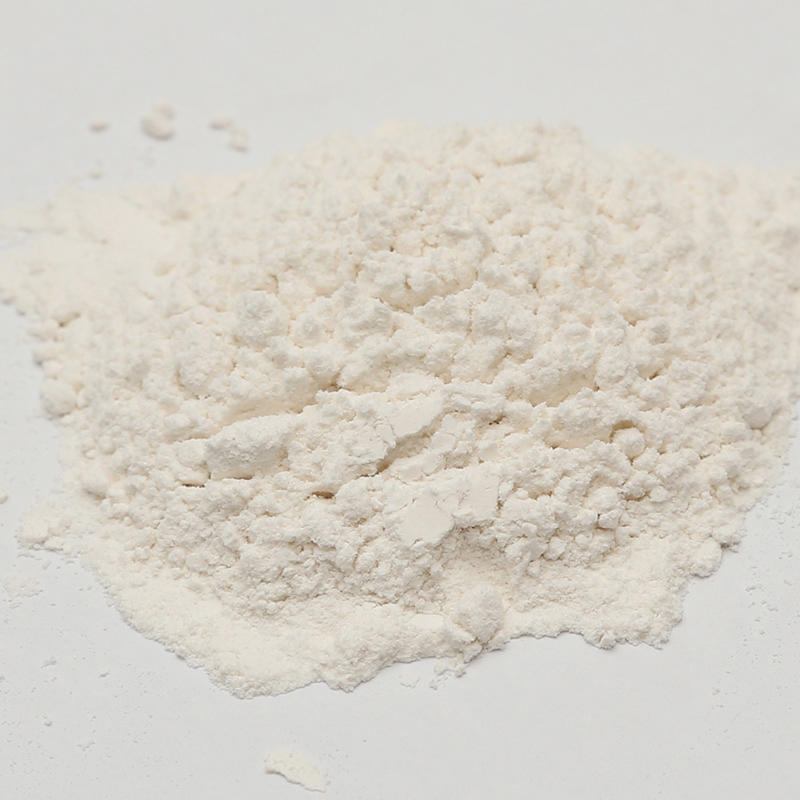

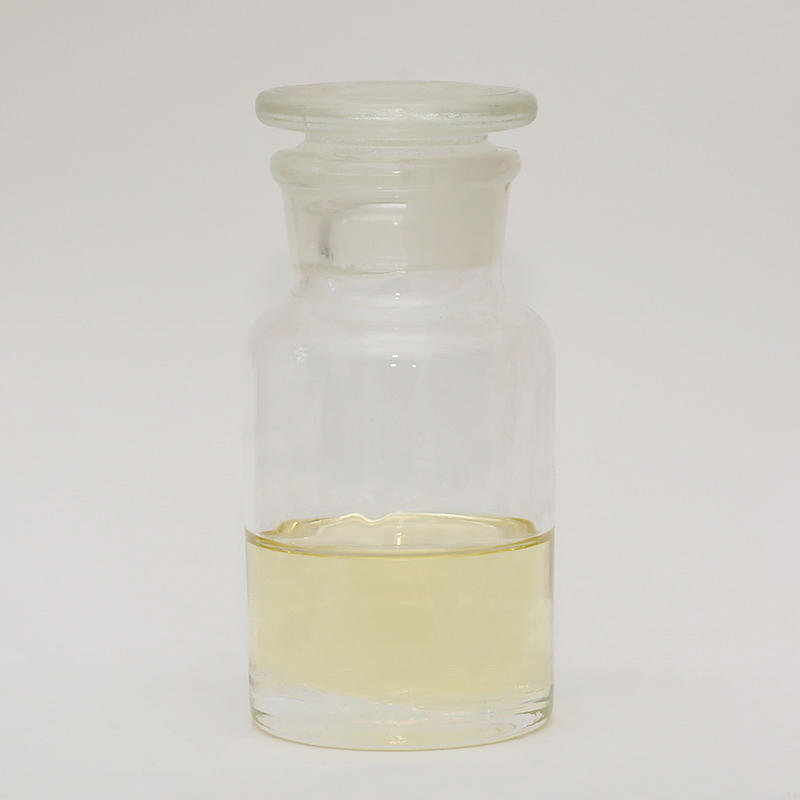

Some coumarone resins are viscous liquids, and some are solid, with a light yellow to black color. The relative density is 1.05-1.15; the relative density of the liquid is 1.05-1.07. The softening point is 75~135℃. The glass transition temperature is 56°C. The refractive index is 1.60~1.65. The iodine value is generally 23~39 g I2/100g. It looks like rosin, soluble in organic solvents such as chlorinated hydrocarbons, esters, ketones, ethers, hydrocarbons, most resin oils, nitrobenzene, anilines, etc., insoluble in water and lower alcohols; excellent acid and alkali resistance, water resistance ; Good electrical insulation, aging resistance, and heat resistance; thermoplastic and corrosion resistance; poor light resistance, flammable, and non-toxic. The solid coumarone resin is hard and brittle, looks like rosin, and has thermoplasticity.

Mainly used to replace natural resin or esterified rosin, configure insulating coatings and anti-rust coatings, etc., and can also be used in rubber, tires, triangle belts, conveyor belts, paints, inks, waterproofing, hoses and other industries, ceramic adhesives, plastics Plasticizers, etc. Whether it is a solid resin or a liquid resin, the rubber alone has no adhesion; after compounding, the rubber can have good adhesion, including pressure sensitivity or hot melt. Coumarone resin added to rubber can play a role in softening, strengthening, thickening, dispersing, etc., thereby improving the processing performance of the rubber.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体