Physical and chemical properties

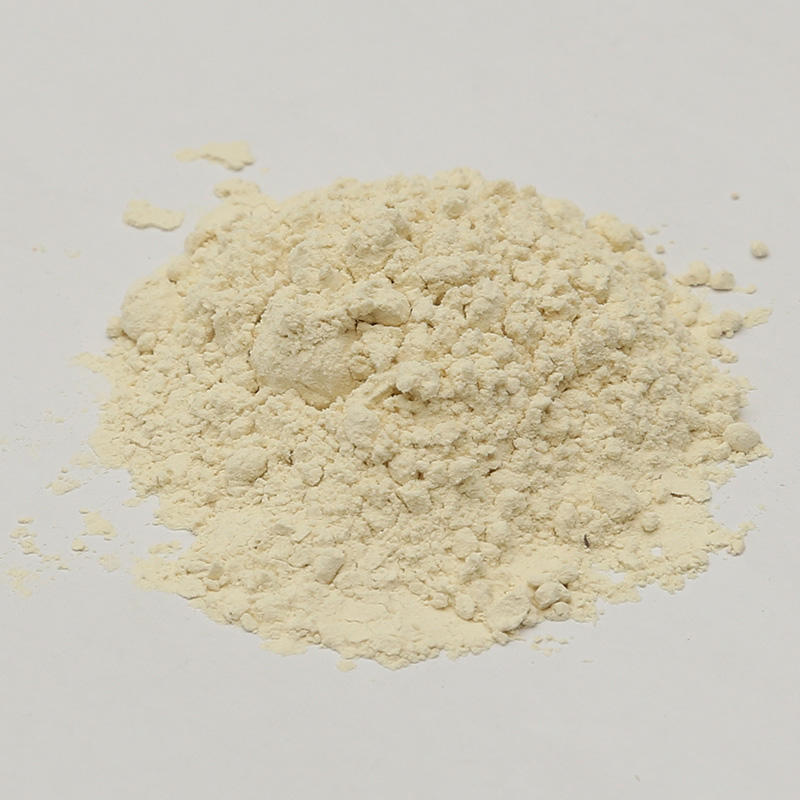

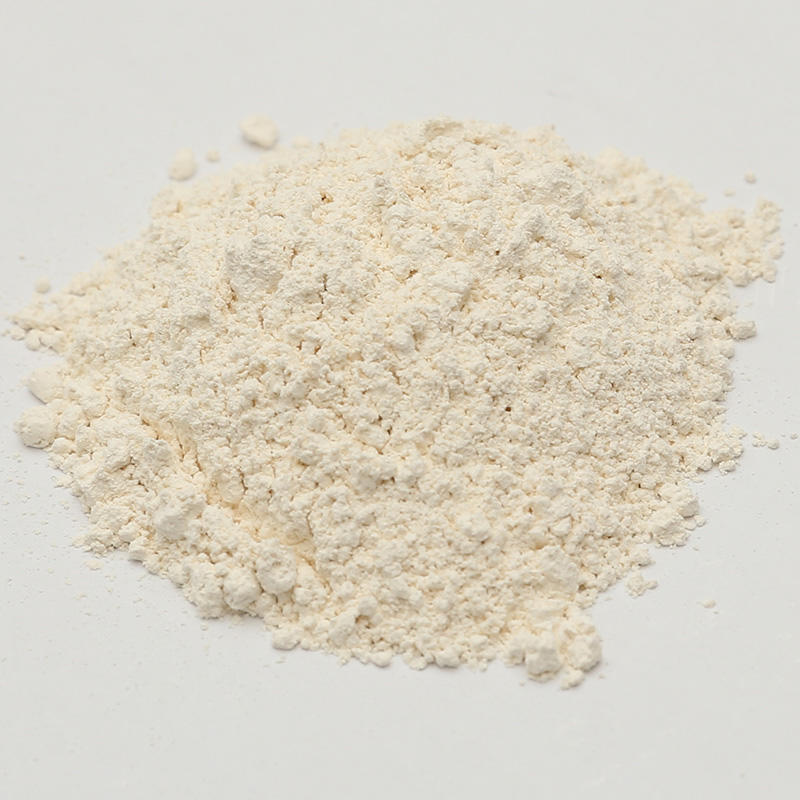

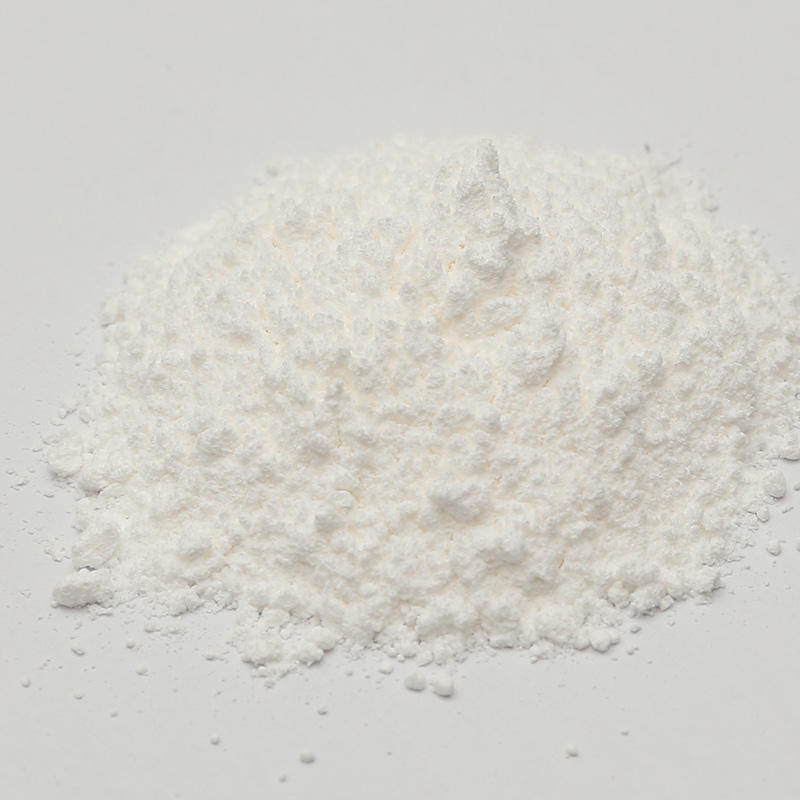

Coumarone resin is a viscous liquid or solid, with a relative density of 1.05 to 1.15; liquid relative density of 1.05 to 1.07. The softening point is 75~135℃. The glass transition temperature is 56°C. The refractive index is 1.60~1.65. The iodine value is generally 23~39 g12/100g. It looks like rosin, soluble in organic solvents such as chlorinated hydrocarbons, esters, ketones, ethers, hydrocarbons, most resin oils, nitrobenzene, anilines, etc., but insoluble in water and lower alcohols. Excellent acid and alkali resistance and water resistance. Good electrical insulation, aging resistance, and heat resistance. Shows a neutral reaction. It has thermoplasticity and corrosion resistance. The light fastness is poor, Combustible, Non-toxic.

The quality index of solid coumarone resin:

Index name Premium product First-class product Qualified product

Chromaticity (according to standard colorimetric fluid) ≤ 3 5 9

Softening point (ring and ball method)/℃ 80~90 80~90 80~90

pH value (acidity meter method) 5~9 5~9 4~10

Moisture/%≤0.3 0.3 0.4

Ash/%≤0.15 0.5 1.0

Foreign brands include Cumar R-12, 16 (United States), Paradenel 35 (United States).

Use

Coumarone resin is widely used in rubber, tires, triangle belts, conveyor belts, paint, ink, waterproof, hose and other industries. No matter it is coumarone resin, liquid coumarone or rubber alone, it has no adhesion, and it is compounded. Later, it can make the rubber have good adhesion, including pressure sensitivity or hot melt. In the past, the adhesive was mostly used for natural rosin resin or indenene resin. The price is high, the source is unstable, and the performance is not as good as coumarone resin. At the same time, the price of coumarone resin is lower than that of rosin, and the output of coumarone resin is more stable than that of rosin. Coumarone resin has occupied a dominant position in adhesives in industries such as rubber. Coumarone resin added to rubber can play a role in softening, strengthening, thickening, dispersing, etc., thereby improving the processing performance of the rubber.

Application method

Coumarone resin has good compatibility with rubber and is a solvent-based tackifier, plasticizer and softener. Liquid products are good tackifiers with slightly lower reinforcement; solid products, especially high softening point products, are better reinforcing agents, which can improve the mechanical and physical properties and aging resistance of the rubber, but the viscosity is not as good as that of liquids. Malone resin. Dosage of 3-6 parts can dissolve sulfur, help disperse sulfur and carbon black, and prevent scorching. Liquid products are used as tackifiers and plasticizers for natural rubber and synthetic rubber (except butyl rubber), and can also be used as regenerating agents for reclaimed rubber. Solid products can be used as organic reinforcing agents for styrene butadiene rubber, nitrile rubber and neoprene

English

English Português

Português Español

Español русский

русский 中文简体

中文简体